6

/

66

cabinet from falling.

After the screen installation and connection is completed, do not step on the plug,

socket, power/signal cable.

Please use the accessories/accessories specified by our company.

2.3 Warning Statement

Do not open the internal equipment of the cabinet to reduce the risk of electric

shock. If modules has dead lamps, or the parts of the cabinet are damaged,

professional maintenance personnel should be required for maintenance.

If the power cord in the cabinet is damaged, do not try to repair the power cord.

Please replace the power cord with professional maintenance personnel.

Moisture-proof: The maximum relative humidity of the work should be less than

90% .

Dustproof: Do not place the display in a dusty environment and clean the surface

of the display regularly.

Dehumidification: Do not adjust the screen directly to the maximum brightness,

but gradually increase it.

Temperature and humidity range:

Working temperature and humidity range -30 ~ 50

℃

/ 10% ~ 90%

Storage temperature and humidity range -30 ~ 60

℃

/ 10% ~ 95%

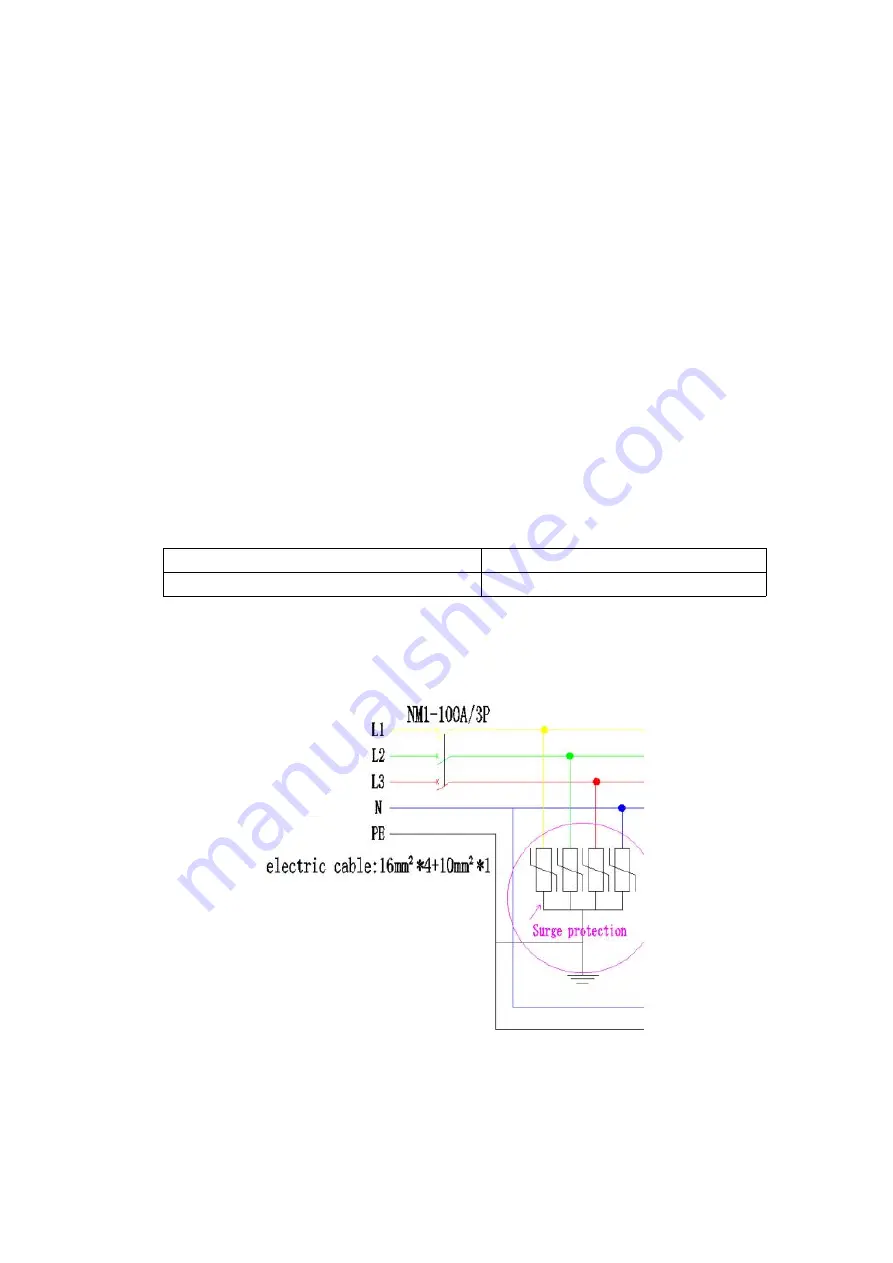

Each main power cable can carry a maximum current of 16A. Note that the total

current of the cabinets cascaded in one main power cable should not exceed

16A. Refer to Table 7-1 for the specific quantity.

Surge protection device of power should be added in the power distributor

.

After the display is idle for a period of time, please turn on the power and input the

signal for the first time, and adjust the brightness of the display to the lowest level

for about half an hour and gradually increase the brightness gradually, then use it

normally.

Summary of Contents for VMR-O P3.9

Page 1: ...1 66 Product Manual VMR O P3 9 ...

Page 41: ...41 66 C 5 Plastic hammer ...

Page 49: ...49 66 ...

Page 53: ...53 66 F8 Press the lock handle according to the mark to lock the cabinet as shown below ...

Page 55: ...55 66 G4 Open the back cover of the power supply cabinet as shown below as shown below ...