Troubleshooting _ 27

Problem

What To Do

Will Not Lock

• Perform Quick Test Mode. Check Door Lock.

Check the resistance for door lock. if Approx 0.2 ohm between the terminal of contact (white-Red wire),

and if not, change PCB(refer to PCB connector check).

• Read Lock Switch and PCB . (Refer to PCB Connector Check.)

Will Not Unlock

• Flash “HOT LED ”. Turn off and on the unit. If “flashing HOT LED” keeps illuminating, check PCB and Door Lock Switch.

• Read Lock Switch and PCB . (Refer to PCB Connector Check.)

• Perform Quick Test Mode. Check Door Lock. Check the resistance for door unlock if Approx 0.2 ohm between the

terminal of contact (white-blue wire), and if not, change PCB(refer to PCB connector check).

No Key Operation

• Option and Function buttons respond differently according to each cycle.

• Child Lock is being activated. To exit, hold down Spin level key and soil level key simultaneously until it sends out

a beeping sound.

• When “End“ illuminates on the display, only Power button works. Press Power button and make new cycle selections.

Will Not Drain

• Check for any kink on the drain hose. If any, straight it out.

• Check for any restriction in the drain hose.

• Close the door and press the Start/Pause Button. For safety reasons, the washer does not tumble or spin with the

door open.

• When it is freezing outside, check if it is frozen inside the drain hose.

• Check if the water level signal input is correct. Go to Board Input Test Mode.

• Go to Quick Test Mode and do Drain Pump Test.

• Check if there is any twist in the hose (the one between Tub and Drain Pump).

• Check if it reads AC 120V at the pump when a spin cycle is selected.

• Read the winding resistance of the pump motor. (15±10% Ohms)

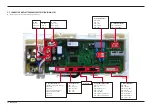

• Check the pump at Pin #3 of CN6 and pin #7 of CN4 on PCB. It should read AC 110~120V. (Refer to PCB Connector Check)

Wrong Water

Temperature

• Check if both of the water taps are fully open.

• If the water heater is located far from the washer, screw out the hot water tap and let its water pass until you get

hot water.

• Too Hot/Too Cold: Reduced amount of water is supplied while PCB controls the influx to regulate the actual

temperature of the water in the tub. This may appear to be significantly hotter/colder than expected.

• Check if the temperature selection is correct.

• Disconnect inlet hoses from the Water Valve and remove any residue in the inlet screens.

Noisy and/

or Vibration/

Walking

• Check if the washer is leveled and the lock nuts are tightened up on the bottom plate.

• Check if all of the shipping bolts and spacers are removed from the back panel.

• Check if load is big enough and there is no unbalance. If there is not enough load, put in a few towels to balance it.

• Check if the motor is fastened enough.

• Remove various trouble contributors (such as dust coat on the floor).

Buttons do not

Respond

• Option and Function buttons respond differently according to each cycle.

• Child Lock feature has been selected. To disable feature press and hold Temp and Spin simultaneously until a beep

is heard.