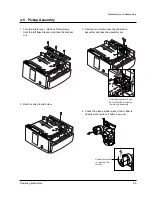

1. Before disassembly, pull the power plug from the AC

power connector.

2. To avoid spilling toner inside the machine, do not turn

the printer over or on its side before removing the

developer cartridge.

3. Faulty installation of DRAMs may cause permanent

damage to the Laser Printer.

4. Use only+5V power for video controller-related circuit-

ry.

5. When replacing parts, use only the same type of part

as the original. Replacing components with a second

vendor’s part may cause faulty operation.

6. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples :

metal panels and input ports).

7. Insulation Checking Procedure:

Disconnect the power cord from the AC power

source. Connect an insulation resistance meter

(500V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see left)

should be greater than 1 megaohm.

8. Never defeat any of the B+ voltage interlocks. Do not

apply AC power to the unit (or any of its assemblies)

unless all solid-state heat sinks are correctly installed.

9. Always connect a test instrument’s ground lead to the

instrument chassis ground before connecting the pos-

itive lead; always remove the instrument’s ground

lead last.

1-2

Samsung Electronics

Precautions

1-2 Servicing Precautions

Note : Requirements for AC power are described on the label affixed to the rear of the printer. Check the AC

voltage rating requirement before use.

CAUTION : Be sure the power is off to the chas-

sis or circuit board, and observe all

other safety precautions

1. Immediately before handling any semiconductor com-

ponents assemblies, drain the electrostatic charge

from your body by touching a known earth ground.

Alternatively, wear a discharging wrist strap device.

(Be sure to remove the strap before applying power

to the unit under test to avoid potential shock.)

2. After removing ESD-equipped assembly, place it on a

conductive surface such as aluminum foil to prevent

accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a ground-tip soldering iron when soldering

or desoldering ESDs.

5. Use only anti-static solder removal device. Some sol-

der removal devices are not rated as “anti-

static;”these can accumulate sufficient electrical

charge to damage ESDs.

1-3 ESD Precautions

Some semiconductor (“solid state”) devices are easily damaged from static electricity. Such components com-

monly are called Electrostatically Sensitive Devices (ESDs); examples include integrated circuits (ICs), Large-

Scale Integrated circuits (LSIs), some field-effect transistors, and semiconductor chip components. The follow-

ing techniques will reduce the occurrence of component damage caused by static electricity: