20

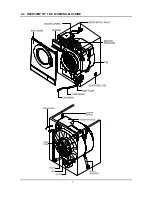

1) Capacity : AC 230V/1900W

2) Location : Bottom of TUB

3) Function : Raise the water temperature

supplied at the wash process.

4) Resistance value : 23~29

Ω

5) Thermal Fuse : 128°C

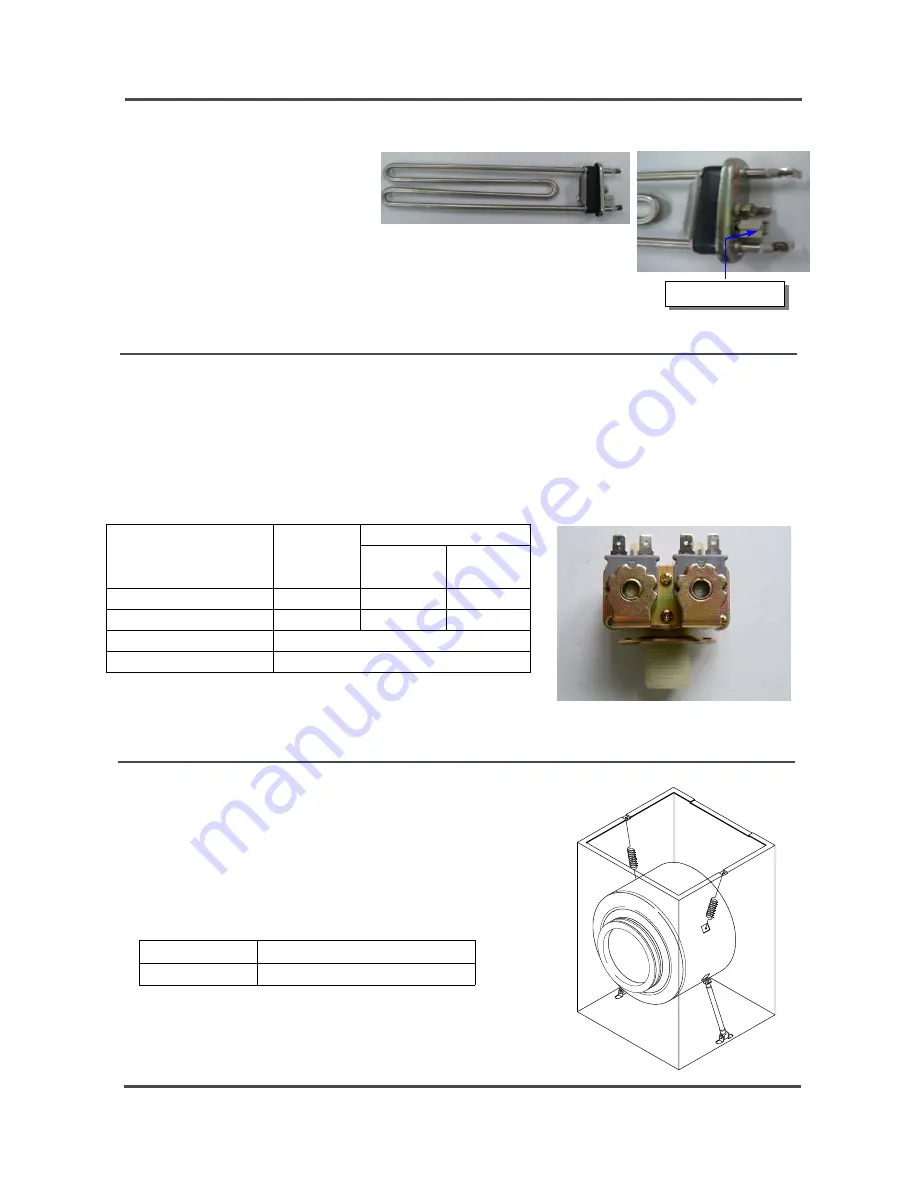

3-5-4. Detergent tub and water supply value

A Detergent tub is composed of housing and 3 drawers . supplied water flows into the 3 drawer-detergent

tub by way of classifier at each washing process.

three open drainage way with detergent and supplied water by way of connector located under the housing

flows into washing tub.

the water supply valve is composed of a hot water valve(1 way) and a cold water valve(2way) and water

flow per Min in the valve is below.

3-5-5. Shock absorber and buffer spring

This wash machine is equipped with 2 Shock absorbers with same

capacity and with 2 buffer springs. 2 Shock absorber are placed

under the tub and outside case , 2 buffer springs are placed on the

right and left of the upper side of outside case.

Shock absorber function: during wash, dehydration absorb the shock.

buffer spring: buffering the vibration

device

capacity of Shock absorber

Shock absorber

8±2 kg

Hot water

valve(1 way)

Cold water valve (2 way)

V1

V2

water flow(L/min)

10

ℓ

10

ℓ

5

ℓ

resistance value

4.4

㏀

4.2

㏀

4.2

㏀

power consumption

AC 220v ~ 240V 50/60

㎐

usable water pressure

0.5 ~ 8

㎏

/

㎤

Thermistor

3-5-3.

Heater

Summary of Contents for WF-F1256

Page 16: ...6 2 2 OVERVIEW OF THE WASHING MACHINE...

Page 19: ...9 3 PRODUCT SPECIFICATIONS 3 1 OVERVIEW OF THE CONTROL PANEL...

Page 42: ...50 9 SCHEMATIC DIAGRAM 9 1 EMZ F1256 F1056...

Page 43: ...51 9 2 ROLD F856...

Page 53: ...51 9 SCHEMATIC DIAGRAM 9 1 EMZ F125AC F105AV...

Page 54: ...52 9 2 ROLD F85A...

Page 55: ...51 9 SCHEMATIC DIAGRAM 9 1 EMZ F125AC F105AV...

Page 56: ...52 9 2 ROLD F85A...