Troubleshooting _ 23

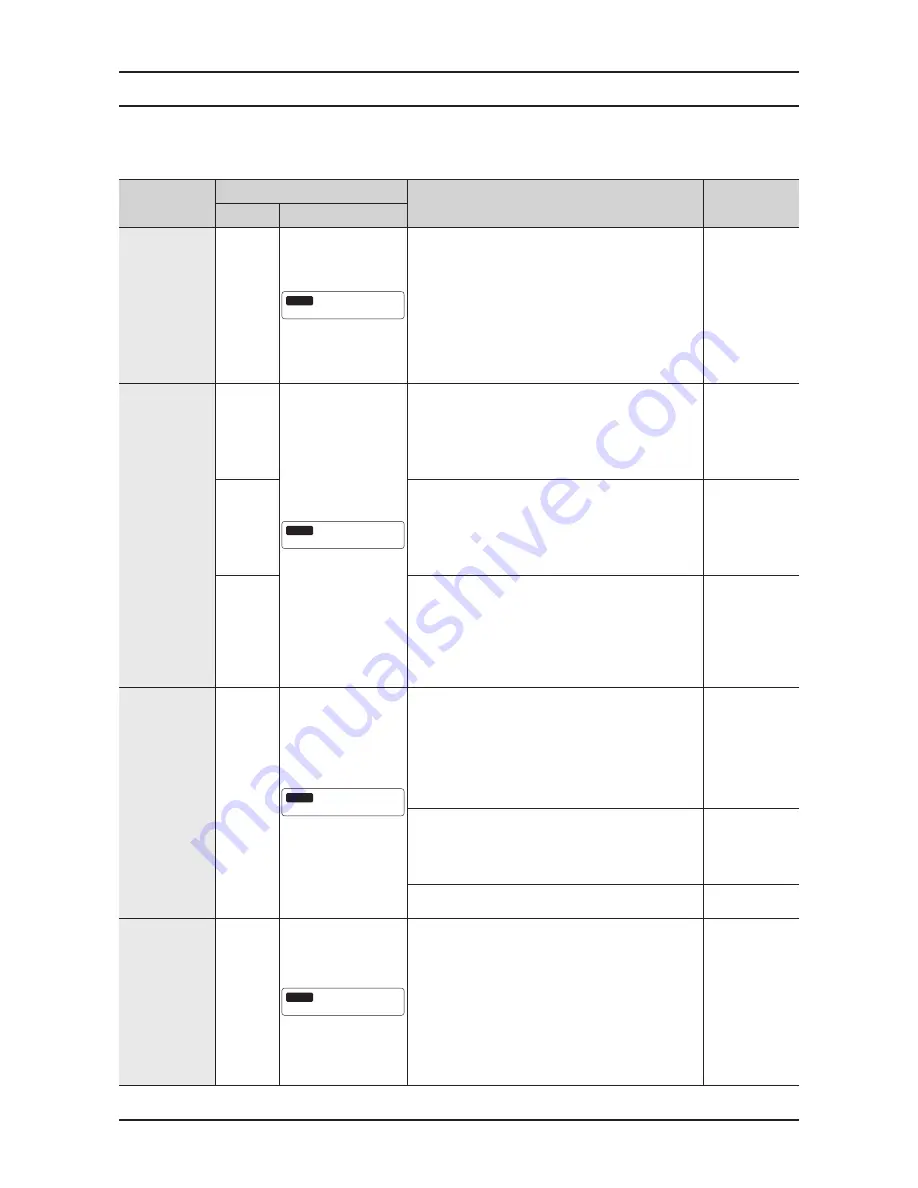

4. TROUBLESHOOTING

4-1. ERROR MODES

►

This is a washer integrated error mode. For detailed information, refer to the general repair scripts.

Error Type

For USA

Causes

Remarks

LED

LCD

Water Level

Sensor

LE1

Water Level Sensor Problem

ERROR!

- The part of the hose where the water level sensor is

located is damaged (punctured).

- The hose is clogged with foreign material.

- The hose is folded.

- Too much lubricant has been applied to the insertion

part of the air hose.

- Hose engagement error (disengaged)

- Part fault (Faulty internal soldering)

- The water level sensor terminal is disengaged.

- Main PBA fault.

Motor Driving

Error and Hall

Sensor Error

3E

The Motor is not working

properly.

ERROR!

- The PBA connector terminal is not connected.

- The motor spin net is not engaged.

- The motor’s internal coil is damaged (short-circuited

or cut)

- The hall sensor terminal is not connected.

- Foreign material (a screw) has entered the motor.

This error

occurs because

of restrained

revolutions

E3

- Motor overloaded due to too much laundry (Non-

sensing)

- The motor hall sensor terminal is not connected.

- PBA fault

- The motor driving error from the PBA is weak.

: Unstable relay operation, etc.

This error

occurs when an

interference is

generated due

to too much

laundry, etc.

bE

- This occurs due to erroneous operating signals from

the motor hall sensor.

- The IPM terminal of the main PBA is not connected.

- The DD motor cover is out of place.

- The PCB housing terminal is not connected.

- PBA fault

- DD motor fault

Water Supply

Error

nF

Low Water Pressure

ERROR!

- Foreign material is entering the water supply valve.

- The water supply valve terminal is not connected.

(Wire disconnected)

- The warm water and rinse connectors are wrongly

connected to each other.

- This occurs if the PCB terminal from the drain hose

to the detergent drawer is not connected. Check

whether the transparent hose is folded or torn.

If this error

occurs in the

Wool course

- The cold and warm water supply hoses are wrongly

engaged into each other.

- The temperature of the water supplied through the dry

valve during a dry cycle is sensed as higher than 70

˚C.

The water

supplied for 1

minute drying

the drying cycle

is 0.3 ~ 0.4 L.

- The water temperature is sensed as higher than 50 ˚C

in the Wool or Lingerie courses.

Drain Error

nd

No Draining

ERROR!

- The pump motor impeller is damaged internally.

- The wrong voltage (220 V → 110 V) is supplied to the

parts.

- Part fault

- This occurs due to freezing in the winter season

- The drain hose is clogged. (Injection error, foreign

material)

- Clogged with foreign material

- The water pump terminal is not connected: rubber

band, bills, cotton, hair pins, coins have collected

inside the drain pump ASSY.

Summary of Contents for WF511AB series

Page 12: ...10 _ Features and Specifications MEMO...

Page 34: ...32 _ Troubleshooting MEMO...