Troubleshooting _ 27

4-2. CORRECTIVE ACTIONS FOR EACH ERROR CODE

►

These

are

co

mmon

troublesh

ooting

procedures

for

each

drum

-type

washer

error

mode.

For

detailed

information,

refer

to

the

general

repair

scripts.

Error T

ype

Error Mode

Causes

Corrective

Actions

Description of Photo

LED

LCD

W

ater

Level

Sensor

LE1

W

at

er

Le

ve

l S

en

so

r P

ro

bl

em

ERROR!

•

W

ater

level

sen

sor

fault

•

Incorrect

connections

of

the

water

level

sensor

terminal

•

The

hose

part

for

the

water

level

sensor

is

folded.

•

Main

PCB

fault

•

Check

the

water

level

sensor

term

inal

connections

and

contacts.

•

An

error

occurs

if

an

incorrect

water

level

sensor

is

used.

Make

sure

to

check

the

material

code.

(Abnormal

operation)

•

If

the

water

level

sensor

is

faulty

,

replace

it.

•

If

the

error

persists

despite

taking

the

action

above,

replace

the

PBA.

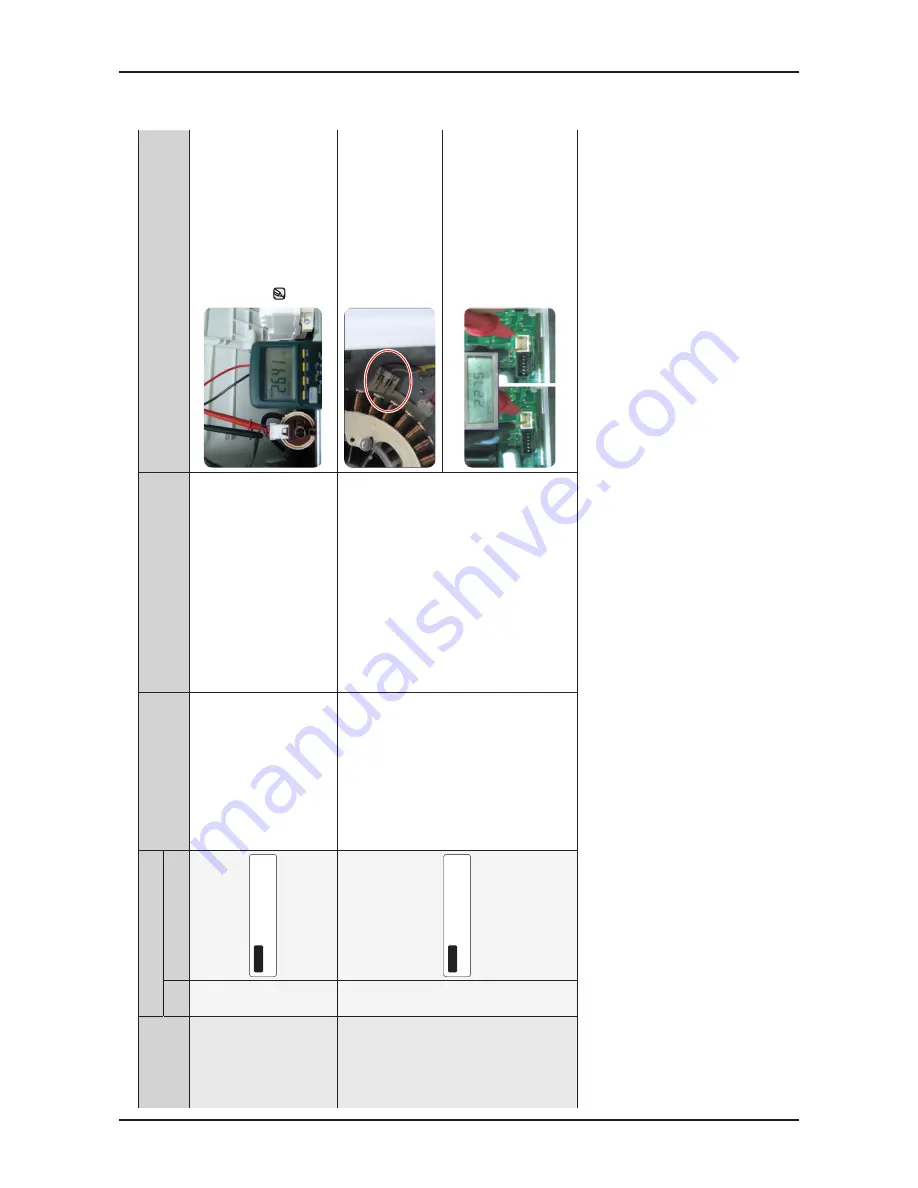

Check

the

water

level

sensor

frequency

.

-

Check

it

after

th

e

water

level

sensor

and

the

connector

are

connected.

Checking

Part

:Pink

Color

Wire

Oragne

Color

Wire

-

Frequency:

Approx.

26.4

KHz

with

no

load

W

ashing

Motor

Error

and

Hall

Sensor Error

3E

E3

bE

Th

e Motor is not w

orking

properly

.

ERROR!

•

W

ashing

motor

fault

•

W

ashing

motor

hall

sensor

fault

•

Incorrect

connections

of

the

washing

motor/hall

sensor connector

•

W

ashing

motor

rotor

and

stator

fault

•

Main

PCB

fault

•

Check

the

motor

connector

termin

al

connections

and

contacts.

•

3E

is

displayed

because

overload

ing

occurs

due

to

too

much

laundry

.

•

If

the

hall

senso

r terminal

is

faulty

,

replace

the

hall

sensor

.

•

Check

whether

the

stator

of

the

m

otor

cover

is

damaged.

•

Check

for

coil

disconnections

due

to

foreign

material.

•

If

the

P

BA

control

circuit

is

faulty

,

replace

the

PBA.

►

Check

the

motor

Winding

Coil

Plug

out

the

connector

and

read

resistances

at

any

two

of

the

three

terminals

on

Motor

: Should

be

6.0

Ω

(at

25°C)

►

Check

the

motor

Hall

Sensor

Check

the

resistance

on

the

main PCB motor

(Between

pins

1

and

3,

and

1

and

4

of

the

four

(4)

pins)

-

Resistance

: Approx.

2

to

4

MΩ

-

Check

the

voltage

when

the

power

is

on.

Summary of Contents for WF511AB series

Page 12: ...10 _ Features and Specifications MEMO...

Page 34: ...32 _ Troubleshooting MEMO...