Media and tray

49

2. Menu Overview and Basic Setup

-

Condition:

Do not use labels with wrinkles, bubbles, or other

indications of separation.

•

Make sure that there is no exposed adhesive material between labels.

Exposed areas can cause labels to peel off during printing, which can cause

paper jams. Exposed adhesive can also cause damage to machine

components.

•

Do not run a sheet of labels through the machine more than once. The

adhesive backing is designed for only a single pass through the machine.

•

Do not use labels that are separating from the backing sheet or are wrinkled,

bubbled, or otherwise damaged.

Card stock/ Custom-sized paper

•

In the software application, set the margins to at least 6.4 mm (0.25 inches)

away from the edges of the material.

Summary of Contents for Xpress M267 Series

Page 3: ...3 BASIC 5 Appendix Specifications 116 Regulatory information 126 Copyright 139 ...

Page 44: ...Media and tray 44 2 Menu Overview and Basic Setup ...

Page 78: ...Redistributing toner 77 3 Maintenance 4 M2670 M2671 M2870 M2880 series 1 2 ...

Page 79: ...Redistributing toner 78 3 Maintenance 5 M2675 M2676 M2875 M2876 M2885 M2886 series 1 2 ...

Page 91: ...Cleaning the machine 90 3 Maintenance ...

Page 98: ...Clearing original document jams 97 4 Troubleshooting 2 Original paper jam inside of scanner ...

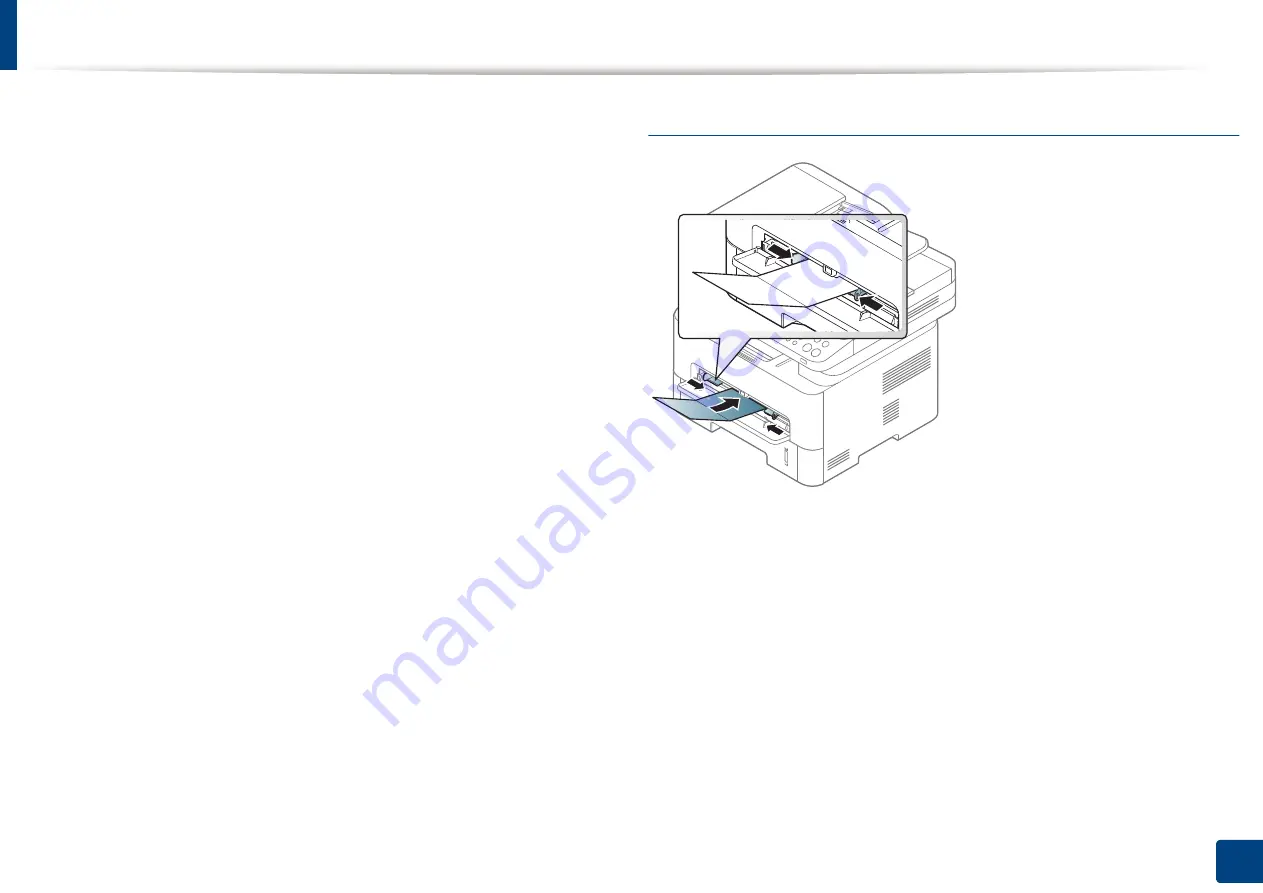

Page 101: ...Clearing paper jams 100 4 Troubleshooting 5 In the manual tray ...

Page 103: ...Clearing paper jams 102 4 Troubleshooting M2670 M2671 M2870 M2880 series 1 2 ...

Page 104: ...Clearing paper jams 103 4 Troubleshooting M2675 M2676 M2875 M2876 M2885 M2886 series 1 2 ...

Page 105: ...Clearing paper jams 104 4 Troubleshooting 7 In the exit area ...

Page 106: ...Clearing paper jams 105 4 Troubleshooting 8 In the duplex unit area ...

Page 139: ...Regulatory information 138 5 Appendix 27 China only ᆇ 䋼 ...

Page 141: ...Copyright 140 5 Appendix ...