27

insufficient holding force wire

will fall from rotator. Replace

the rotator.

The rotator holder and rotator

operating spring are responsible

for alignment of the wire beneath

the bender bar grooves. The

position of the rotator holder

determines how far the rotator

is pushed forward under the

bender bar by the rotator

operating spring (Index L). A

weak spring will not push the

rotator in far enough and with

this improper alignment the

bender bar will knock the wire

from the rotator or will shear

the wire into pieces. To secure

proper alignment, check the

position of the rotator operating

spring. Make any necessary

adjustment of the rotator holder

or replace the rotator operating

spring if weak.

The wire is fed into the rotator

and held for forming. If the

rotator is dirty, the wire is not

gripped securely enough and drops out. Remove

and clean the rotator. If the edges over which the

wire is formed are sharp, the corners of the stitch

crown will fracture. Remove the rotator and polish

the edges with a fine emery cloth.

To remove, Adjust or Replace the Rotator Holder:

1. Swing the rotator operating spring to the left.

2. Remove the rotator.

3. Loosen the rotator holder screw (Index N).

4. Adjust the rotator holder screw.

5. Re-assemble.

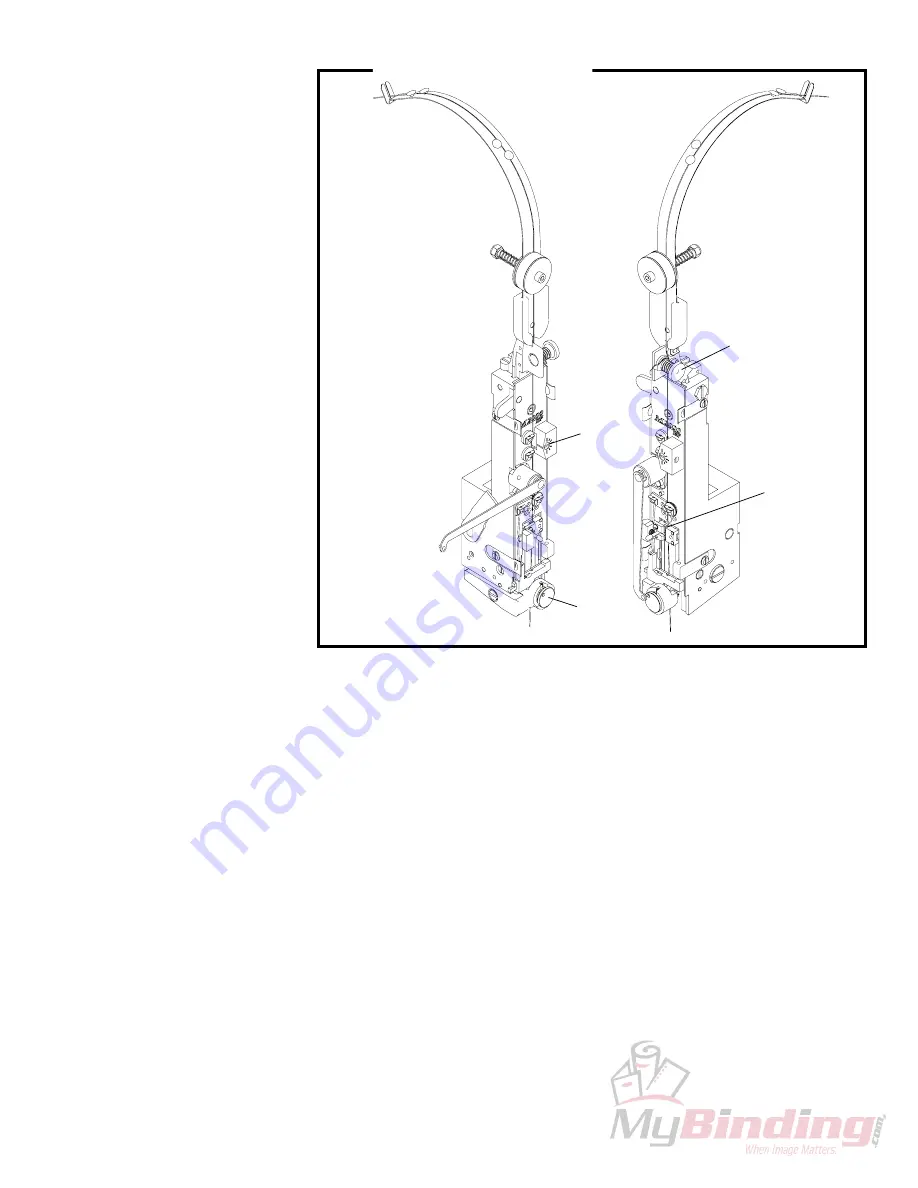

P. Wire Straighteners: (Figure 30)

All coils of stitching wire have a certain amount of

bundle curve. The purpose of a wire straightener

is to remove this curve. There is both an upper

wire straightener (Index A) and a lower wire

straightener (Index B) on all M2000 Model Stitchers.

See "Threading Wire and Adjusting Wire

Straighteners" page 6.

The upper wire straightener should feed wire parallel

to the faceplate. This insures that the wire will

properly enter the rotator and will be aligned with

the grooves in the bender bar. If the wire is not

parallel to the face plate the wire is sheared in the

rotator as the bender bar descends. Adjust the

upper wire straightener.

The lower wire straightener directs the wire straight

down so that it enters the rotator (Index C). If the

wire is not straight enough it hits the rotator and

buckles. Adjust the lower wire straightener so that

the wire points straight down as in figure 30.

Improper straightening of the wire can also cause

the stitch legs to buckle or turn out because they

strike the clincher improperly. Excessive tension

on the wire straightener prevents the grip (Index D)

from feeding the wire smoothly. This causes

variation in leg length.

NOTE:

Check the wire straighteners when changing the

coils to insure the accurate feeding of wire.

Figure 30

(CTTT2605T3 Scene 3, 4)

A

B

C

D

Summary of Contents for ISP BinderyMate 2 305

Page 22: ...19 NOTES...

Page 42: ...39 NOTES...

Page 45: ...42 Section 7 ELECTRICAL ELECTRICAL SCHEMATIC 115 V A C SK828...