9

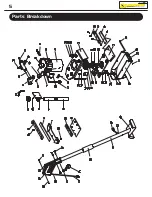

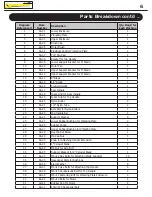

Contents List

Prior to setting up the SAMURAI Industrial

Floor Stripper, check that the following items

are enclosed:

Item

Quantity

Check if enclosed

SAMURAI Industrial Floor Stripper Unit

1

____Yes ____No

Extension Handle for SAMURAI

1

____Yes ____No

Bag of accessories for the SAMURAI, including nut driver,

blades, bolts, and support mounts

1

____Yes ____No

SAMURAI Industrial Floor stripper Operator’s Manual

1

____Yes ____No

If any of these items are missing, please contact your local authorized dealer at once.

DO NOT ATTEMPT ASSEMBLY OR OPERATION WITHOUT ANY OF THESE LISTED PARTS!

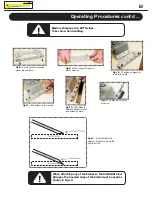

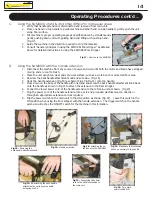

Before using the SAMURAI Industrial Floor stripper, please perform the following procedures for the per-

sonal and property safety of the operator and jobsite and for optimal performance.

1. Before operating the fl oor stripper

ensure

that it is

structurally

and

mechanically safe

by checking the

following:

a. Perform a detailed visual inspection on the machine with particular attention to the following:

i. Are there any loose, worn or damaged parts? If so, DO NOT ATTEMPT TO OPERATE THE

MACHINE. Make note of required parts, and contact your authorized service centre for

replacement parts and further assistance to service the unit PRIOR to any further use.

ii. Is the machine, particularly the cutting blade and support mounts, clean and free of debris?

Small debris and other foreign objects can jam machine and cause the unit to malfunction,

leading to serious injury to the operator and property damage on the jobsite.

iii. Are the blades and support mounts balanced and securely attached to the fl oor stripper?

iv. Are there any cracks or damage on the machine? Contact your authorized service centre

immediately for advice and corrective measures. DO NOT ATTEMPT TO OPERATE THE

MACHINE until it is refurbished to factory standards.

b. Inspect the handles and power switch for the following:

i. Are both top and rear handles, as well as the power switch on the main unit properly and

securely attached to the machine?

ii. On the extension handle, are all the sections and pieces secured to each other? Is

the trigger switch working to factory standards? Consult your local health and safety

organization for any pointers for jobsite and machine operation safety.

Pre-Operating Procedures

!

If any of the above checks fail, please take necessary

steps to maintain or repair the unit before operating it

in any environment.