13

B.

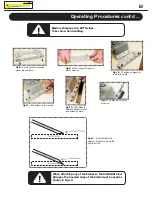

General principles in using the SAMURAI fl oor stripper

The SAMURAI fl oor stripper is designed for use either as a standalone unit for small or diffi cult jobs, such as

stairs, or with the handle extension for clearing large areas. The following instructions apply to both usages.

1. Before connecting the unit to a grounded power source, fl ip ON/OFF switch (Fig.15) between both

positions to ensure that switch works. Press and release trigger switch verify that it is in good working

order.

2. Ensure that the fl oor stripper is completely turned off prior to adjusting or relocating the unit.

3. Verify that electrical power is supplied from a grounded and safe source, and that the source is of the

same voltage to that specifi ed on the machine.

4. If using an extension cord, connect it to the machine, then plug the other end into the grounded

receptacle.

5. Position blade on the surface of the material to be removed.

6. Flip on ON/OFF switch to the ON position and tilt the machine forward, maintaining a steady and

consistent angle. If using with handle extension, pull on trigger.

7. Proceed as fast as the machine will allow. DO NOT FORCE MACHINE TO MOVE AT ANY OTHER RATE.

The nylon wheels at the bottom of the machine (Fig.16) are designed to allow the fl oor stripper to

glide on fl oor surface. These wheels MUST REMAIN IN CONTACT with the fl oor at ALL TIMES. The

fl oor stripper is operating at an incorrect angle if wheels are not touching the fl ooring surface. An

incorrectly positioned fl oor stripper may lead to severe damage to the fl oor, operator and the machine

itself.

8. Blade

must

be

fl ush to the surface that it is scraping AT ALL TIMES. Uneven scraping results and

possible damage to job surface can result otherwise. Depending on the width of blade used, the

machine can remove material from 4” to 9” wide. Account for this working width as job proceeds.

9. If unit does not power on, check that the main power switch is switched ON, and that the unit is

connected to a live, grounded receptacle

Operating Procedures cont’d ...

!

DO NOT USE THE SAMURAI AS A PRY BAR, NAIL REMOVER, OR ANY

OTHER PURPOSES EXCEPT THOSE EXPLCITLY STATED IN THIS MANUAL.

ANY UNAUTHORISED OR NON-RECOMMENDED USE CAN LEAD TO SEVERE

BODILY HARM, JOBSITE & MACHINE DAMAGE.

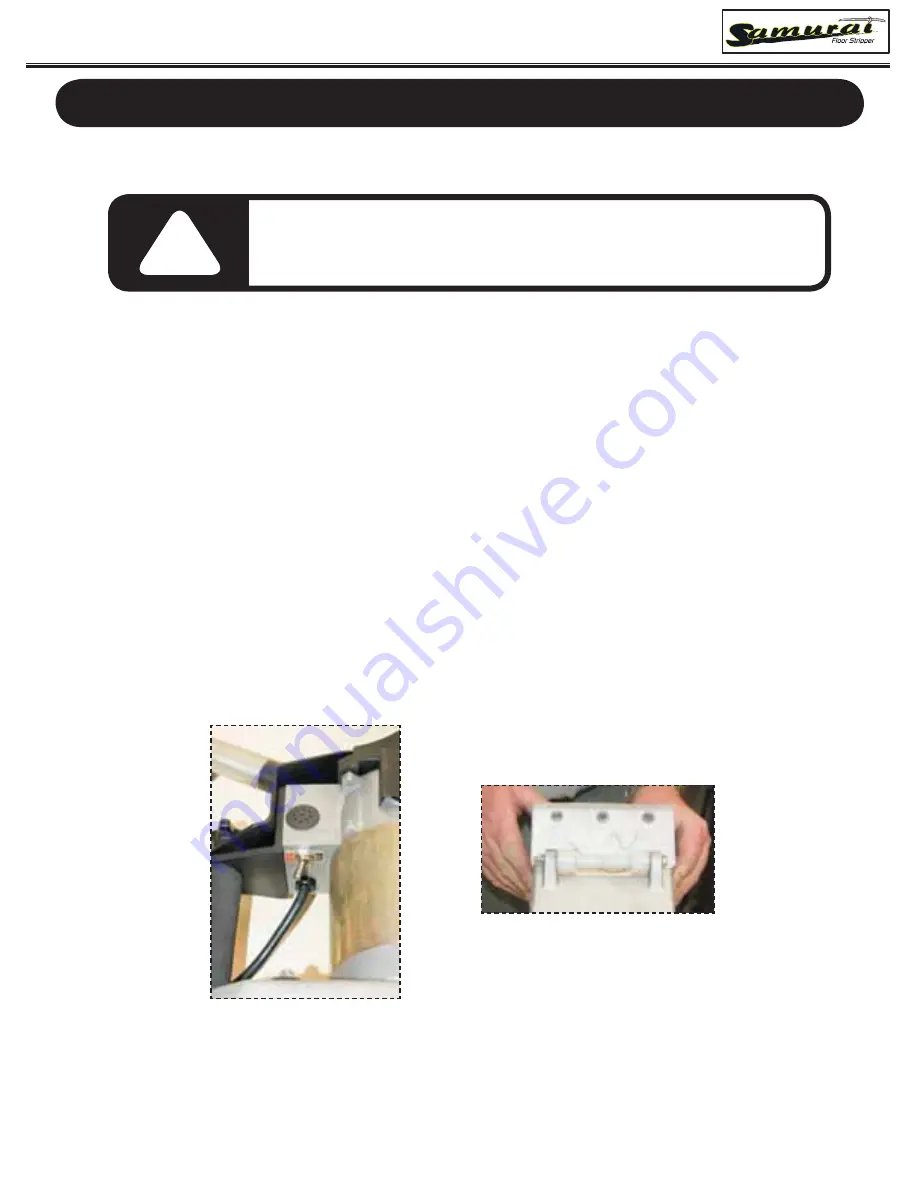

Fig.15:

Location of main power switch

Fig.16:

Location of nylon wheels