1

Pre-Operation Note

Thank you for your purchase of the SAMURAI Industrial Floor Stripper. This fl oor stripper has been designed and

manufactured to our highest quality demands for durability and performance.

We are committed to offering durable products and quality after-market service. The SAMURAI Industrial Floor

Stripper is warranted to be free from manufacturer’s defects in material and workmanship for a period of six (6) months

from the date of purchase. This warranty will be void if the machine has not been operated and maintained in the

manner prescribed in this Operator’s Manual. Any machine malfunctions, and/or warranty claims that arise from the

misinterpretation or the misunderstanding of the instructions and cautions discussed in this booklet will not be eligible for

warranty protection.

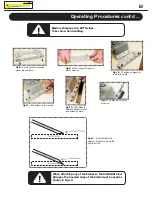

In order for the fl oor stripper to perform at its optimum capabilities, the operator

must read this manual

thoroughly

before using this unit. This Operator’s Manual contains important product operation procedures, safety

precautions, maintenance and troubleshooting tips as well as other advisories. Please keep this manual nearby at all

times when operating the machine as a reference should any questions arise. If the machine is sold or transferred to

another user, please ensure that this manual accompanies it.

The SAMURAI Floor Stripper is designed to remove existing laminate, vinyl and parquet fl ooring.

NOT

RECOMMENDED FOR USE WITH CERAMICS.

The machine should not be used for any other purpose than that

stated above. The inappropriate use of any machine can cause serious damage and/or bodily harm to the environment

and operator. It is imperative that the operator of this equipment be responsible for the operational environment of the

fl oor stripper. Please be prepared and well-informed for all specifi c requirements precautions and work hazards that may

and/or do exist at the jobsite.

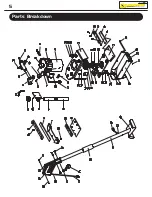

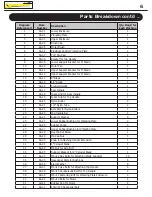

Powered by a 1/2 hp, 5A induction electric motor, the SAMURAI is an industrial-use unit designed to make fl oor

stripping fast and easy. The SAMURAI has many features which are designed to improve your working experience. It

comes with a complete set of accessories, including 3 different kinds of blades and their support mounts to help you

tackle each type of fl ooring with the right tool!

The nut driver included is a handy tool to help you change blades and

perform maintenance quickly and safely. The removable extension handle maximizes comfort and ease of use of the fl oor

stripper for both fl oors and stairways.

In order for you to enjoy the most out of your new fl oor stripper, always keep safety as a priority.

Inspect your

jobsite for any debris such as chipped tiles, glass, wiring, string or any other items that can become hazardous during

work. Ensure that there are no electrical hazards, such as the presence of water, hazardous and fl ammable substances.

Make sure that the main power switch, located on the main unit, is switched OFF when there is no operator present.

The jobsite environment, fl oor conditions, job specifi cations and operator experience will all be factors that must be

considered to select the proper tool for the job.

Failure to maintain the fl oor stripper in a proper manner will lead to

decreased productivity of the tool and hazards to the operator and bystanders. Do not use the machine if it has been

modifi ed or improperly maintained.

All jobsites are different. Please ensure that when using the SAMURAI Floor Stripper, all local bylaws and codes

are followed. All operators and mechanics of this machine should be trained in general machine use and safety.

Every care and effort has been made to ascertain the accuracy and completeness of procedures described in this

document to ensure your enjoyment and satisfaction. If you have any questions or concerns, please contact the Service

Department at your authorized dealer.

Pre-Operation Notes