CWFL-800/1000/1500 Series

19

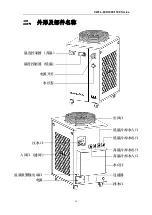

三、安装说明

冷水机安装使用非常简单,新机首次使用可按以下步骤进行:

1

、打开包装,检查机器是否完好,附件是否齐备。

2

、拧开机器注水口,加入冷却水。

加水时应同时观察水位计的水位慢慢加水,注意不要让水溢出!

3

、根据设备情况接好出水管、入水管。

4

、插上电源线,打开电源开关。(严禁无水开机!

)

(

1

)打开电源开关后,冷水机循环泵就开始工作了。新机第一次开机时管路中

会有较多的气泡导致机器偶尔流量报警,运行数分钟后就会恢复正常。

(

2

)第一次开机后,必须马上检查水管管路有无漏水。

(

3

)打开电源后,如果水温低于设定温度,机器的风扇等器件不工作是正常现

象。温控器会根据设定的控制参数自动控制压缩机、电磁阀、风扇等器件

的工作状态。

(

4

)由于压缩机等器件有一个较长的启动过程,根据不同的工况从几十秒到数

分钟不等,所以不要频繁开关机。

5

、检查水箱水位。

新机开机后排空了水管中的空气,水箱水位会略有下降,为了保持水位在

绿色区域,可以再次适量加水。观察并记下当前的水位情况,等冷水机运行

一段时间后再次观察水位计,如果水位下降明显,就要再次检查水管管路的

渗漏情况。

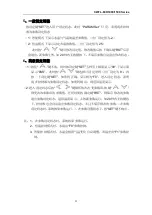

6

、调整温控器参数。

CWFL-800/1000/1500

双温系列冷水机使用的智能温控器一般情况下不

需要调整控制参数,如确实必要的,可参考第

20

页《运行状况与参数调整》。

Summary of Contents for CWFL-800

Page 1: ...CWFL 800 1000 1500 DUAL TEMPERATURE INDUSTRIAL CHILLER USER MANUAL...

Page 15: ...CWFL 800 1000 1500 Series 15 CWFL 800 1000 1500...

Page 16: ...CWFL 800 1000 1500 Series 16 17 18 19 20 23 24 25 28...

Page 18: ...CWFL 800 1000 1500 Series 18...

Page 19: ...CWFL 800 1000 1500 Series 19 1 2 3 4 1 2 3 4 5 6 CWFL 800 1000 1500 20...