CWFL-800/1000/1500 Series

7

(4). RST key: confirm

(5). SET key: setting function

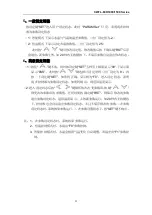

2. Restore to factory settings

Before machine startup, press and hold

keys until the controller

displays rE, 6 seconds later after releasing the keys, the controller works in

normal order. All parameters values settings of the controller have been

restored to factory settings.

3. Alarm function

(1) Alarm Display:

When alarm occurs, the error code and the temperature will be alternately

displayed.

E1

E2

E3

E4

E5

E6

Ultrahigh

room

temperature

Ultrahigh

water

temperature

Ultralow

water

temperature

Room

temperature

sensor failure

Water

temperature

sensor failure

External

alarm input

(2) To suspend the alarm:

In alarming state, the alarm sound could be suspended by pressing any button,

but the alarm display remains until the alarm condition is eliminated.

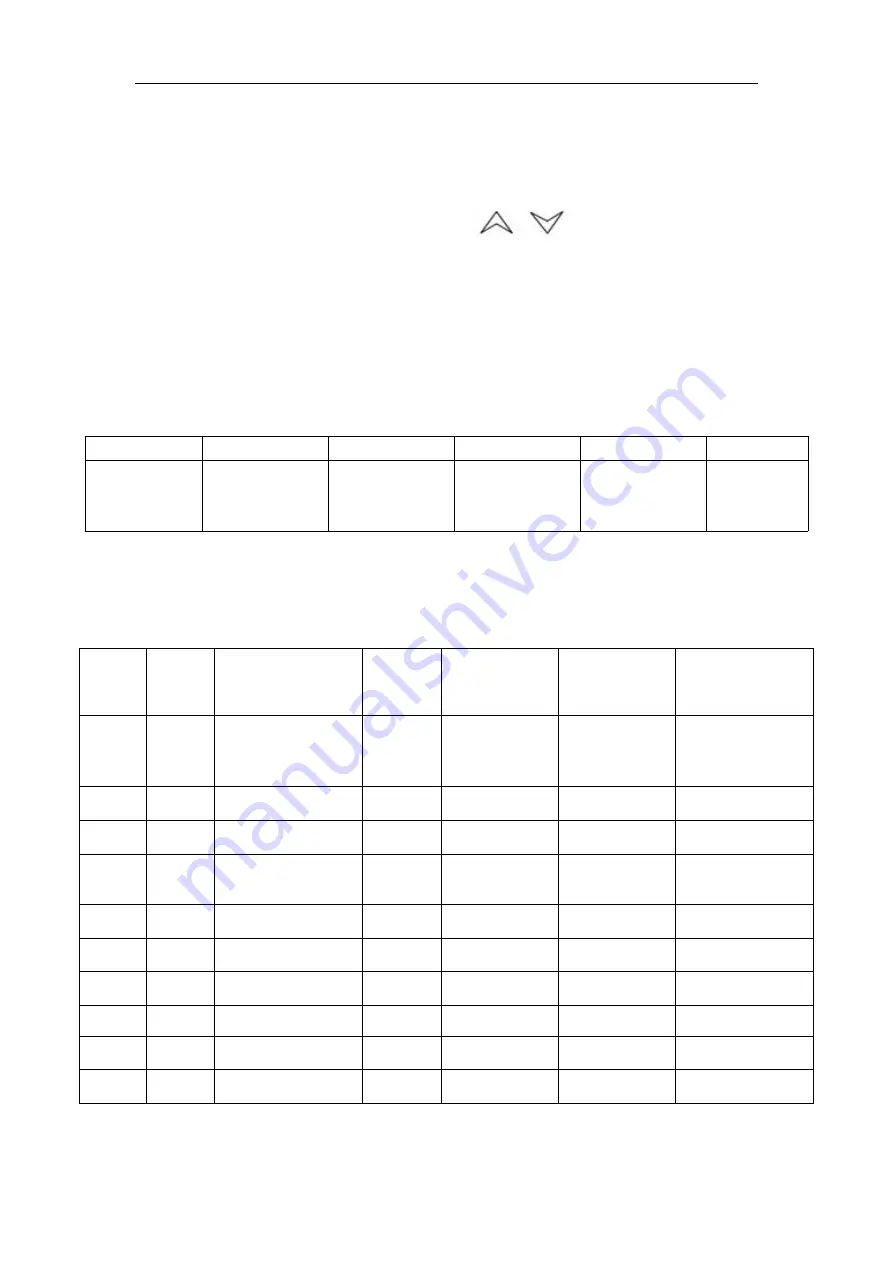

4. Temperature controller parameters list

Order

Code

Item

Range

T-506

Temperature

controller

Factory Setting

T-506H

Temperature

controller

Factory Setting

Note

1

F0

Temperature

setting

F9~F8

30

25

Constant

temperature

control effecting

2

F1

Temperature

Difference values

-15~+5

-2

-2

Intelligent control

effecting

3

F2

Cooling

hysteresis

0.1~3.0

0.3

0.3

4

F3

Way of control

0~1

1

0

1: intelligent

0: constant

temperature

5

F4

Alarm for ultrahigh

water temperature

1~20

10

10

6

F5

Alarm for ultralow

water temperature

1~20

20

15

7

F6

Alarm for ultrahigh

room temperature

40~50

45

45

8

F7

Password

00~99

8

8

9

F8

The allowed highest

water temperature

(

F9+1

)

~40

35

30

10

F9

The allowed lowest

water temperature

1 ~

(

F8-1

)

25

20

Summary of Contents for CWFL-800

Page 1: ...CWFL 800 1000 1500 DUAL TEMPERATURE INDUSTRIAL CHILLER USER MANUAL...

Page 15: ...CWFL 800 1000 1500 Series 15 CWFL 800 1000 1500...

Page 16: ...CWFL 800 1000 1500 Series 16 17 18 19 20 23 24 25 28...

Page 18: ...CWFL 800 1000 1500 Series 18...

Page 19: ...CWFL 800 1000 1500 Series 19 1 2 3 4 1 2 3 4 5 6 CWFL 800 1000 1500 20...