CWUL-05/10/20 Series

15

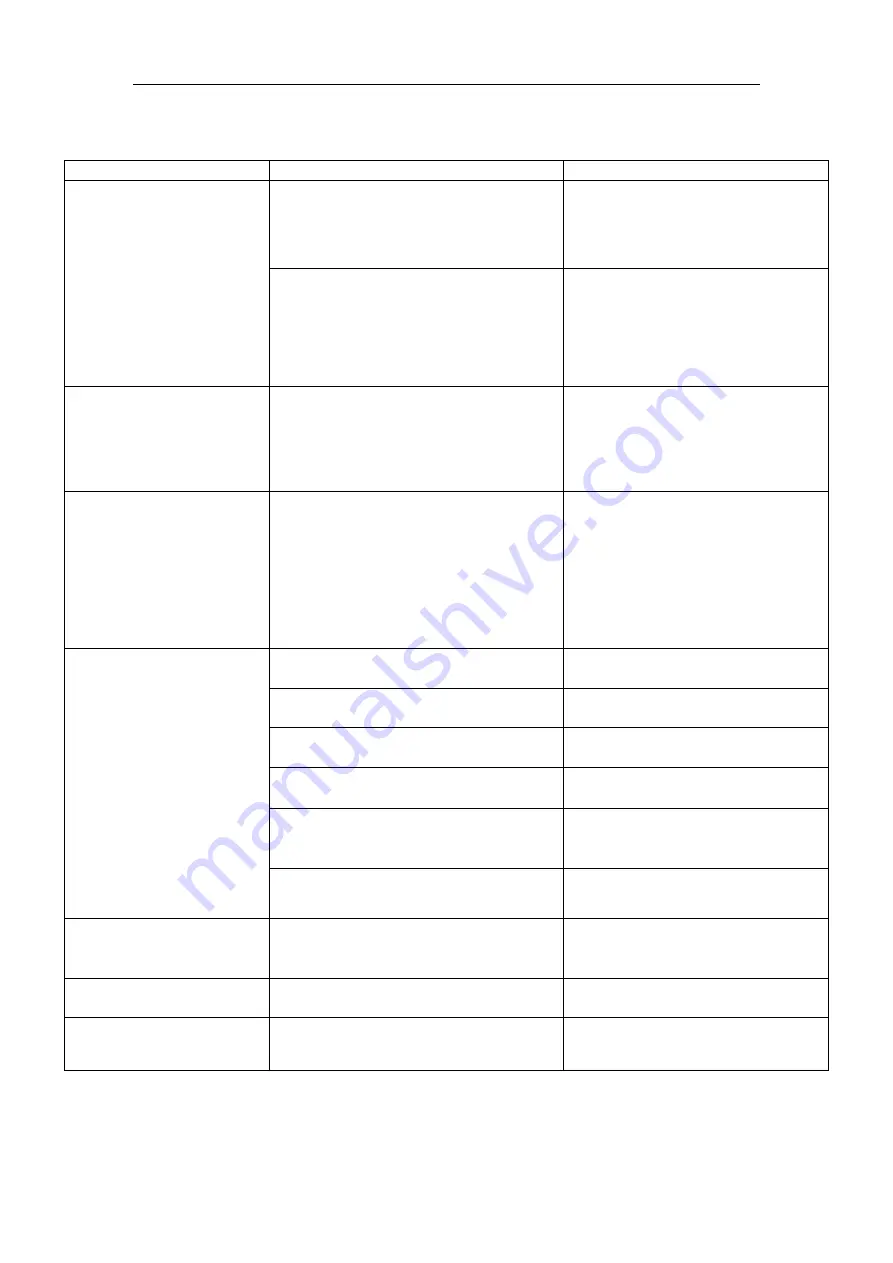

<8> Troubleshooting

Failure

Failure Cause

Approach

Machine turned on but

unelectrified

Power cord is not plugged in place

Check and ensure the power interface

and the power plug is plugged in place

and in good contact.

Fuse burnt-out

Open the electric box cover, check the

protective tube, replace with spare one

if necessary and check whether the

power supply voltage is stable; Check

and ensure the power interface and

the power plug are in good contact.

Flow Alarm

,

use a water pipe

directly connect to the water

outlet and inlet but still

without water flowing

Water level in the storage water tank is too

low

Check the water level gauge display,

add water until the level shown in the

green area; And check whether water

circulation pipe leaks.

Flow alarm occurs while

running with other

equipment, but there is water

flowing and no alarm when

use a water pipe directly

connected to the chiller

water outlet and inlet.

Water circulation pipes are blocked or a

pipe bending deformation.

Check water circulation pipe

Ultrahigh water temperature

alarm

(controller displays E2)

Blocked dust gauze, bad thermolysis

Unpick and wash the dust gauze

regularly

Poor ventilation for air outlet and inlet

To ensure a smooth ventilation

for air outlet and inlet

Voltage is extremely low or astable

To improve the power supply circuit or

use a voltage regulator

Improper parameter settings on thermostat

To reset controlling parameters or

restore factory settings

Switch the power frequently

To ensure there is sufficient time

for refrigeration

(more than 5 minutes)

Excessive heat load

Reduce the heat load or use other

model with larger cooling capacity

Ultrahigh room temperature

alarm

(controller displays E1)

The working ambient

temperature is too high for the chiller

To improve the ventilation to

guarantee that the machine is running

under 40

℃

.

Serious problem of

condensate water

Water temperature is much lower than

ambient temperature, high humidity

Increase water temperature or

to preserve heat for pipeline

Water drains slowly from

outfall during water changing

Injection port is not open

Open the injection port