20

S&C Instruction Sheet 716-504

Installation

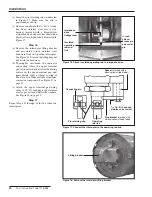

(i) Insert the pin retaining clip as indicated

in Figure 17. Make sure the clip is

positioned as shown.

(j) Remove and discard the

5⁄16

–18

×

2

¼

-inch

hex head stainless steel screw, stop

bracket (marked with a black/yellow

striped label), and spacer (marked with a

black/yellow striped label) illustrated in

Figure 17.

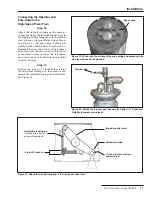

Step 16

(a) Remove the interrupter lifting bracket

and associated ½-inch stainless steel

hardware from on top of the interrupter.

See Figure 18. Discard the lifting bracket

but retain the hardware.

(b) Thoroughly wire-brush the indicator

end-casting where the upper terminal

pad is to be attached as well as the mating

surface on the upper terminal pad, and

immediately apply a liberal coating of

Penetrox A or other suitable aluminum-

connector compound. See Figure 19 on

page 21.

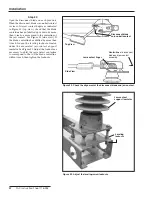

(c) Attach the upper terminal pad using

three ½–13

×

1

¼

-inch hex-head stainless

steel cap screws and Belleville washers.

See Figure 20 on page 21.

Step 17

Repeat Steps 13 through 16 for the other two

interrupters.

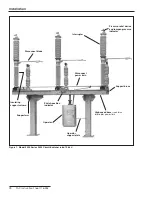

Figure 16 Attach insulated operating rod to interphase drive.

Figure 17. Connect the interrupter to the operating rod link.

Spacer

(marked with a

black/yellow striped label)

Connecting pin

Lifting bracket

Pin retaining clip

Operating

rod link

Stop bracket

(marked with

a black/yellow striped label)

5⁄16

–18

×

2

¼

hex-head

stainless steel screw

½

-inch

silicon-

bronze pin

and cotter

pin

Insulated

operating

rod end

link

s

Interphase

drive

linkage lever

Figure 18. Remove the interrupter lifting bracket.