22

S&C Instruction Sheet 761-515

Installation

Checking Alignment and Adjusting

the Stop Plates

Step 23

NOTICE

The switch should be opened and closed

slowly only when checking for alignment and

complete closure .

When opening or closing the switch in

service, do not slow down or stop part way .

Arcing will occur if the switch is partially

open or partially closed .

Remove the ties holding the switch blades to

their stationary main contact assemblies.

Open and close the switch slowly to ensure

no operational difficulties are encountered

caused by undetected damage in shipping.

Step 24

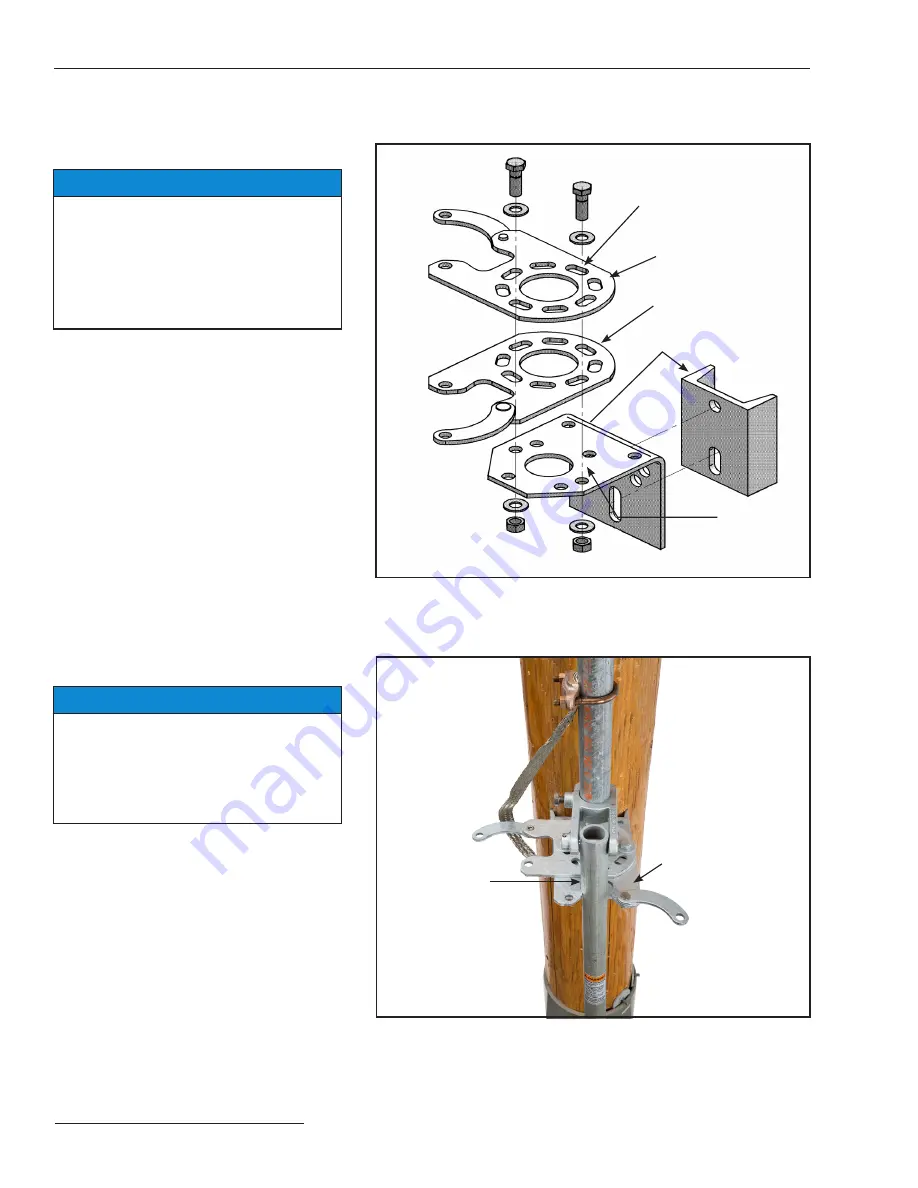

The stop plate holes are slotted to allow room

for adjustment. Loosen the bolts securing

the adjustable stop-plates to the foot-bearing

support plate. See Figure 22. Place the switch

in the fully

Open

position and adjust the

open-position stop plate so the handle, when

lowered, fits into the open-position slot. Mark

the location of the open-position stop plate on

the support plate.

Step 25

NOTICE

DO NOT skip this important step!

Loose

or improperly installed vertical operating

pipe is the primary cause of incomplete

blade contact . Over time this condition can

cause heating and eventually arcing of the

blade contacts .

The most common cause of contact overheating

and damage is not putting enough "wind up"

torque in the vertical operating pipe when the

switch is in the

Closed

position. Wind up is

the torque left in the pipe after the handle is

secured in the closed stop-plate. This windup

prevents the pipe from vibrating in high winds,

and it creates strong positive blade-to-contact

pressure—ensuring the switch is securely held

in the

Closed

position.

Handle against

closed stop-plate

Closed stop-plate

Support plate

Figure 22. Exploded view of stop plates and foot-bearing assembly.

Foot-bearing assembly

Closed stop plate

Open stop plate

Slotted holes

Figure 23. Adjust the closed-position stop plate.