S&C Instruction Sheet 761-545 17

Installation

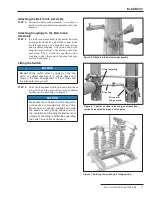

Checking Alignment

STEP 20.

Remove the ties holding the switch blades to

their stationary main contact assemblies. See

Figure 22.

STEP 21.

Remove the 45-degree positioning stud from

each rod guide. See Figure 17 on page 15.

STEP 22.

Open and close the switch slowly to ensure no

operational difficulties are encountered due to

undetected damage in shipping.

WARNING

Open and close the switch slowly ONLY

when checking alignment or making

adjustments to the de-energized switch .

When opening or closing an energized

switch, swing the operating handle

vigorously through its full travel without

hesitation at any point .

Failure to operate the switch properly can

result in arcing, switch damage, serious

injury, or death.

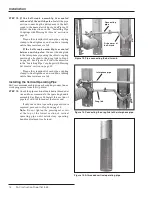

STEP 23.

Move the operating handle slowly to the

Closed

position. See Figure 23. A definite resistance

should be felt at the end of the stroke, indicating

all slack in the operating linkage has been taken

up.

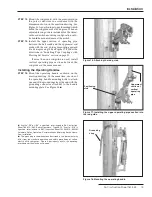

STEP 24.

If there is still slack, repeat the procedure in

Step 18 but move the operating handle more

than 20 degrees in the opening direction before

torquing the clamp bolt on the lowest rod guide

(or bell-crank) coupling. See Figure 24.

Conversely, if considerable force is needed

to move the handle to the fully

Closed

position,

or if the handle does not swing 180 degrees to

the fully

Open

position, loosen the clamp bolt

on the lowest rod guide (or bell-crank) coupling

and move the handle to a position less than

20 degrees from the

Closed

position. Then

torque the clamp bolt on the lowest rod guide (or

bell-crank) coupling. Proper “resistance” in the

operating linkage is essential to ensure positive

switch closure.

Figure 22. Removing the tie at the stationary main contact

assembly.

Figure 23. Verifying the stack has been taken up in the

operating linkage.

Tie

Figure 24. Torquing the clamp bolt at the lowest rod guide

(or bell-crank) cou pling.

Clamp bolt