S&C Instruction Sheet 765-510 17

STEP 12.

Open and close the interrupter switch slowly to

check that no operating diffi

culties are

encountered caused by undetected damage in

shipping. (This applies only when checking for

alignment and complete closure; when in

service, the interrupter switch should be opened

or closed vigorously through its full travel

without hesitation at any point.)

STEP 13.

CAUTION

Adjust the stop plates to remove all excess

play from the operating mechanism and

to attain proper “windup” tension before

energizing the switch.

Slack in the operating pipe may allow the

vertical operating pipe to move or vibrate

during high winds or inclement weather.

Failure to properly adjust the handle may

cause contact overheating or arcing,

damaging the blade contacts. Injury to

operating personnel may result.

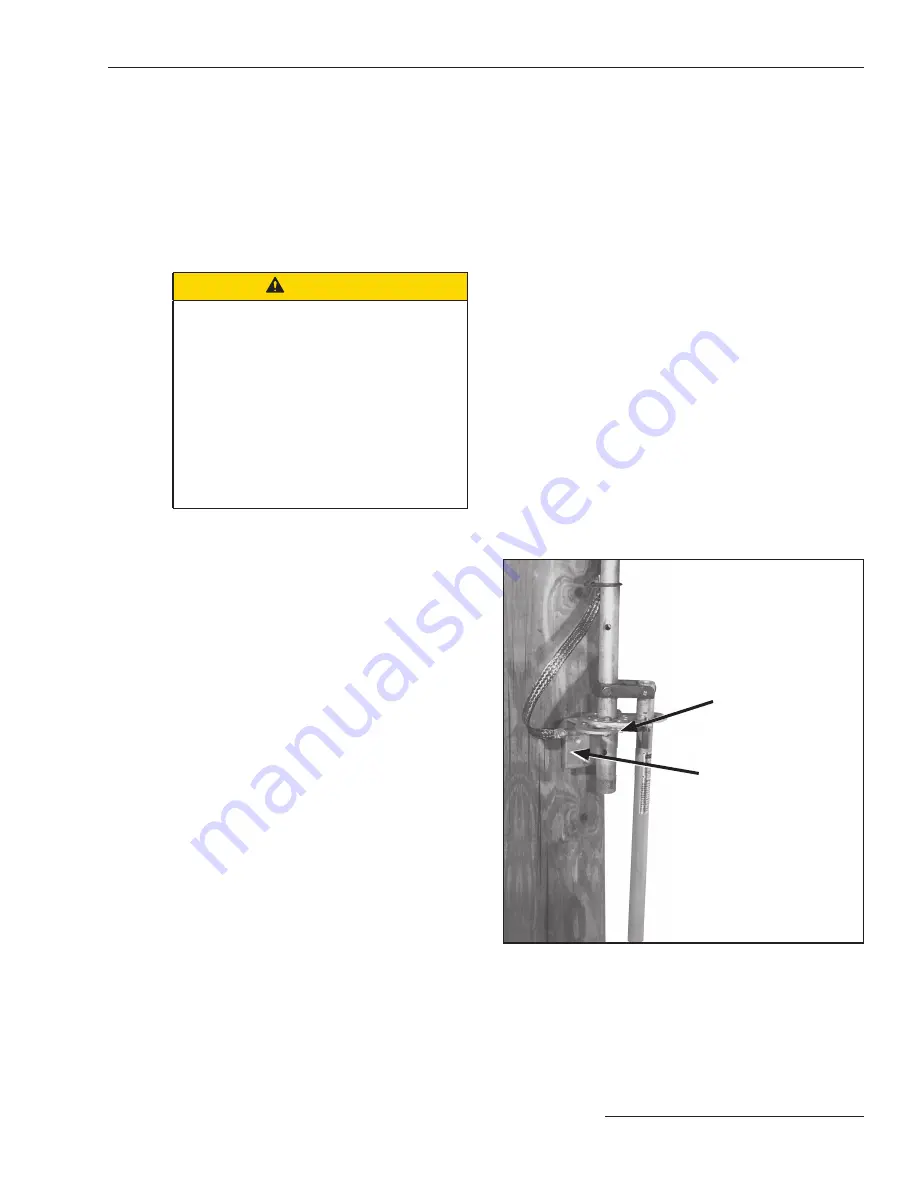

Loosen the bolts that secure the adjustable stop

plates to the foot-bearing support plate. See

Figure 12. Place the switch in the fully

Open

position and adjust the open-position stop plate

so the handle, when lowered, fi ts into the open-

position slot. Mark on the support plate the

location of the open-position stop plate.

Figure 12. The foot-bearing assembly and operating-handle

assembly.

Foot bearing support plate

Adjustable stop plates

Installation

Fully close the switch and apply sufficient

pressure to the handle in the closing direction

to remove all play in the operating-pipe linkage.

Adjust the closed-position stop plate so the

handle will require even greater pressure to

force it into the closed-position slot. Mark on the

support plate the location of the closed-position

stop plate.

While holding both stop plates in the previ-

ously marked positions, torque the bolts to

secure the stop plates to the support plate. Move

the handle to the

Switch-Open

position and

verify the handle, when lowered, fits firmly into

the open-position slot.

Move the handle to the

Switch-Closed

position. Verify all play in the operating-pipe

linkage has been taken up before the handle

can be lowered into the closed-position slot

and substantial pressure is required to force the

handle into the closed-position slot.

STEP 14.

Make sure all clamp bolts and piercing set

screws have been torqued to fi nal tightness.