10

S&C Instruction Sheet 765-500

Installation

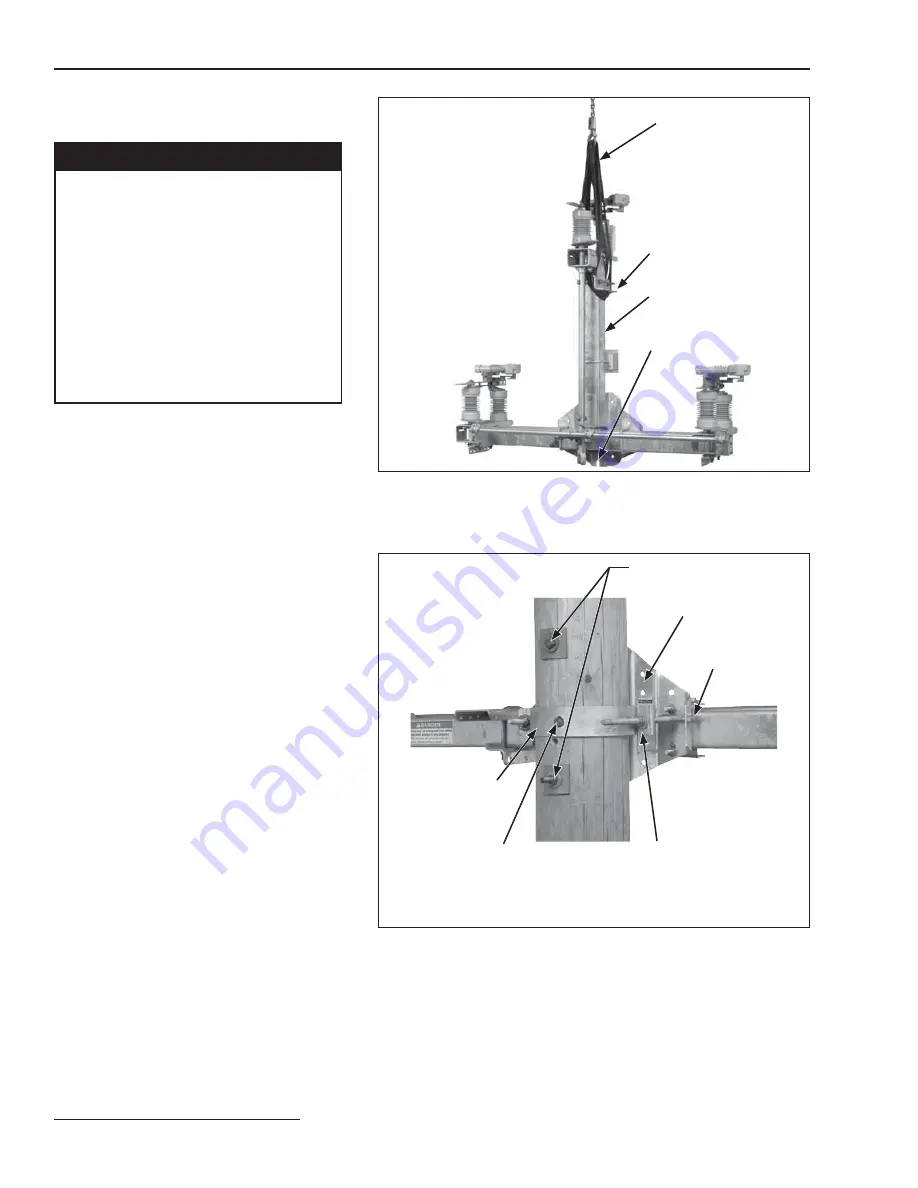

Figure 2. Hoisting Omni-Rupter switch into position for triangular mount-

ing configuration.

Dead-ending

bracket

Vertical support

member

Open slotted hole

Hoisting slings

Figure 3. Typical pole-band attachment detail (upright mounting configu-

ration illustrated).

Pole saddle

Through-bolts

(provided by customer)

¹⁄₂

-inch lag screw

Pole band

J-bolt

¹⁄₄

1

3

stiffening block

Second lag screw installed diagonally opposite on lower corner

of mounting bracket.

Mounting the Switch—Triangular

Mounting Configuration

Ç

WARNING

Lift the switch using the lifting brackets

provided. Do not allow lifting slings to stress

switch parts. Avoid allowing switch to swing

while lifting.

Lifting the switch by the live parts or pole-

unit bases will damage the switch. Rough

handling may cause misalignment of the

blades and contacts.

Failure to lift the switch properly

can result in switch damage, causing

improper operation, arcing or electri-

cal shock.

a. Make sure that the switch is fully closed.

b. Attach lifting slings ONLY to the vertical

switch support member by looping around

the dead-ending bracket and the switch

mounting weldment.

c. Lift switch as shown in Figure 2 until the

lifting slings are just taut.

d. Unbolt the wooden supports from the ship-

ping skid.

e. Slowly and carefully lift the switch to the

proper mounting height.

f. Guide the switch so that the through bolts

projecting from the utility pole slip into the

holes in the switch’s pole-saddle. (The pole-

saddle is provided with a keyhole and an

open slotted-hole for ease of installation.)

g. Securely tighten the through-bolts.

h. Remove the lifting slings from the switch.

Installing the Optional Pole Band

Step 4

Secure the pole-band (optional) to the mounting

bracket on the switch, using the J-bolts pro-

vided. See Figure 3. Two

¹⁄₄

1

3

stiffening

blocks are furnished to be used behind the pole-

band flanges, and underneath the J-bolt nuts.

Lag the pole band to the back side of the pole

through the hole in the center of the band, using

one of the three

¹⁄₂

-inch diameter lag screws

provided. Then, lag the mounting bracket to the

pole using the two remaining

¹⁄₂

-inch lag screws

as shown in Figure 3.

Summary of Contents for Omni-Rupter

Page 28: ...Printed in U S A...