627-500

21

INSTALLATION

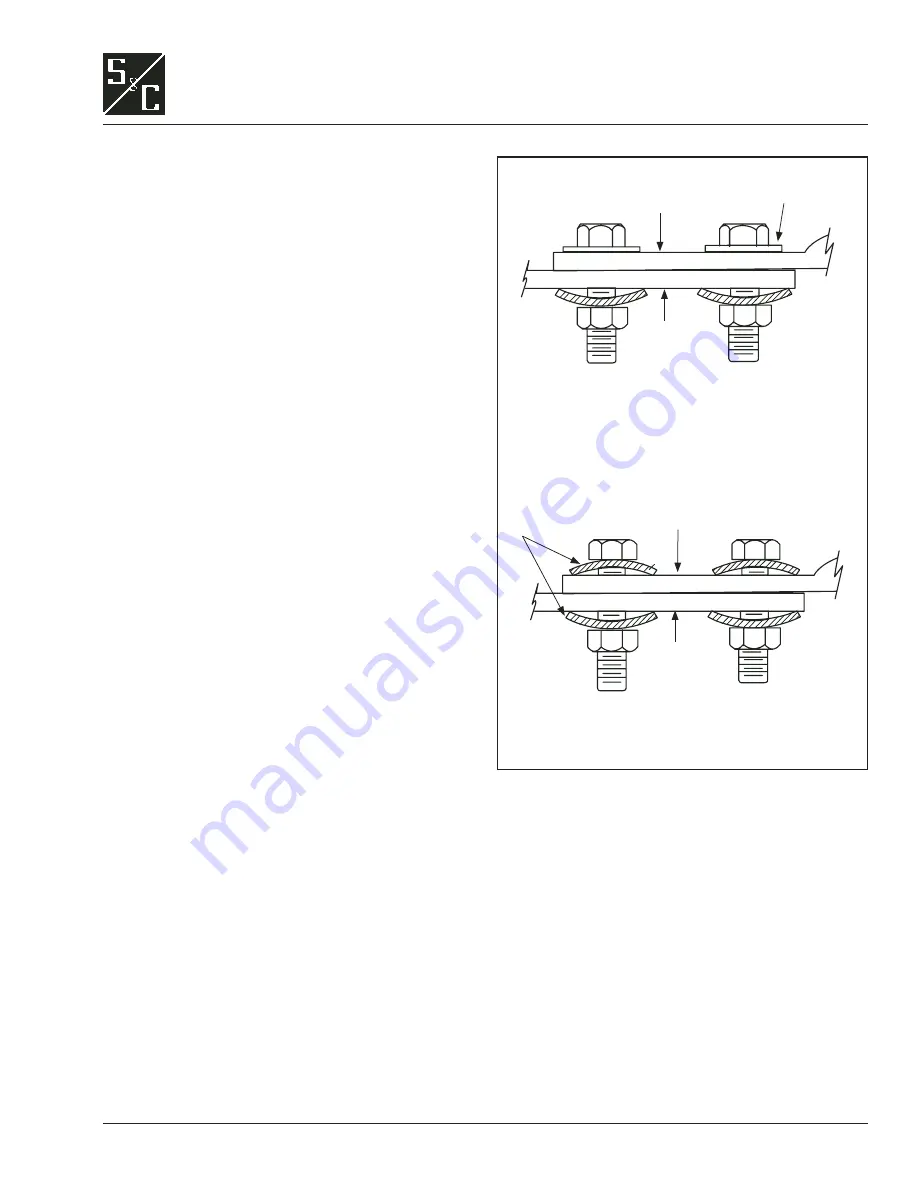

Step 23

Make up the terminal pad connections.

NOTE:

Torque values apply only to the

¹⁄₂

-i nch h a rdwa re de scr ibed a nd not t o

connectors used to secure primary leads of

voltage transformers or surge arresters to

the bus.

(a)

For aluminum terminal pads to tinned-

copper or tinned-bronze connectors

(untinned-copper or untinned-bronze

connectors are not recommended), use

¹⁄₂

-inch galvanized steel hardware, with one

Belleville washer (not furnished) against the

aluminum terminal pad and one galvanized

steel fl at washer against tinned connector,

as shown in Figure 17, Detail A. Tighten

steel bolts to 50 foot-pounds using a torque

wrench. If a torque wrench is not available,

tighten until the Belleville washers are fl at,

and then back off one-half turn. Do not use

lockwashers with Belleville washers.

(b)

For aluminum terminal pads to alumi-

num connectors

, use

¹⁄₂

-inch aluminum or

galvanized steel hardware with two Bel-

leville washers (not furnished) as shown in

Figure 17, Detail B. Tighten aluminum bolts

to the manufacturer’s specifi cations. Tighten

steel bolts to 50 foot-pounds using a torque

wrench. If a torque wrench is not available,

tighten until the Belleville washers are fl at,

and then back off one-half turn. Do not use

lockwashers with Belleville washers.

Figure 17. Terminal pad connections for aluminum terminal

pads.

Copper connector

Aluminum connector

Belleville

washers

Aluminum

terminal pad

Flat washer

Aluminum

terminal pad

Detail A,

for aluminum terminal pads to

tinned-copper or untinned-bronze connectors

Detail B,

for aluminum terminal pads to

aluminum connectors