20 S&C Instruction Sheet 461-502

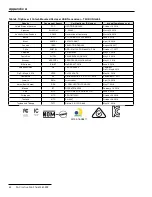

Factory Default Settings

All TripSaver II reclosers are shipped with the factory

default settings shown below. These settings will protect

the overhead power line in case an unconfigured TripSaver

II recloser is installed. Use the configuration kit and the

S&C TripSaver II® Service Center Configuration Software

to properly configure a TripSaver II recloser before putting

it in use.

NOTICE

Failure to properly configure a TripSaver II recloser

in accordance with applicable codes and standards

can result in slow or no response to a fault level and

miscoordination . Settings should be determined and

approved by qualified persons who are familiar with

the principles of selective coordination and system

protection .

Default TCC Curve Settings

•

Initial Trip (1st curve)

: Microprocessor recloser:

S&C 104 cur ve; minimum trip current: 100 A;

time multiplier: x1

•

Open Interval After Initial Trip

: 5 seconds

•

Sequence Coordination

(disabled by default):

Microprocessor recloser: S&C 133 curve; minimum trip

current: 100 A; time multiplier: 2

•

Coordination Reset Time

: 120 seconds

•

Test 1 (2nd curve)

: Microprocessor recloser: S&C 104

curve; minimum trip current: 100 A; time multiplier: x1

•

Open Interval After Test 1

: 5 seconds

•

Test 2 (3rd curve)

: Microprocessor recloser: S&C 133

curve; minimum trip current: 100 A; time multiplier: x2

•

Open Interval After Test 2

: 5 seconds

•

Test 3 (4th curve)

: Microprocessor recloser: S&C 133

curve; minimum trip current: 100 A; time multiplier: x2

•

Sequence Reset Time

: 15 seconds

Default NR Curve Settings

•

Standard NR: Microprocessor recloser

: Definite

time; minimum trip current: 100 A; time: 0 seconds

•

Post-Fault Wakeup NR Curve

:

Microprocessor

recloser: definite time; minimum trip current: 100 A;

time: 0 seconds

•

Cold Wakeup NR Curve

: Microprocessor recloser:

definite time; minimum trip current: 100 A; time:

0 seconds

Default LCD Screen Settings

•

Screen to display when recloser is dropped-open

:

Primary Normal

screen

•

Language

: English

•

Normal screen

:

Primary Normal

screen

•

Number of times the display screen sequence

repeats

: 2 times

•

Duration of each display screen item

: 3 seconds

•

Display screen items

:

Primary Normal

screen;

load current; last fault magnitude; number of open

operations; remaining contact wear in %; LCD screen

temperature; software versions

Default Communications Settings

•

Communication Mode

:

Non-Gateway

mode

•

Side-magnet Radio Enabling Function

: Enabled

Default Local Manual Open Settings

•

Function

: Disabled

Operation