18

S&C Instruction Sheet 461-500

Operation

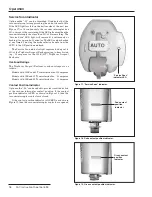

Service Soon Indicator

Option suffix “-L1” can be furnished. It indicates that the

vacuum interrupter is approaching the end of its useful life.

If the LED light located on the bottom side of the unit (see

Figure 17) is lit continuously the vacuum interrupter has

20% or more of life remaining. If the LED is flashing then the

vacuum interrupter has less than 20% of life remaining. The

“Service Soon” LED light will remain lit (continuously or

flashing) for a period of 5 minutes. The LED can be checked

at any time by moving the mode selector handle from the

AUTO to the NR position and back.

The Service Soon indicator light requires load, equal to

30% of the TripSaver Dropout Recloser rating, to be activated

(e.g., 30 amperes for the 100K (65T) TripSaver Dropout

Reclosers.

Overload Ratings

The TripSaver Dropout Recloser overload ratings are as

follows:

Models with 100K and 65T control modules: 110 amperes

Models with 50K and 30T control modules: 55 amperes

Models with 30K and 20T control modules: 35 amperes

Contact Position Indicator

Option suffix “-L2,” can be added to provide visual indication

of the vacuum interrupter contact position. If the contact

position indicator is RED as shown in Figure 18, then the

vacuum interrupter contacts are closed.

If the contact position indicator is GREEN, as shown in

Figure 19, then the vacuum interrupter contacts are opened.

Figure 17. “Service Soon” indicator.

“Service Soon”

indicator LED

Figure 18. Red contact position indicator.

Figure 19. Green contact position indicator.

Red contact

position

indicator

Green contact

position

indicator

Summary of Contents for TripSaver

Page 24: ......