S&C Instruction Sheet 695-510

9

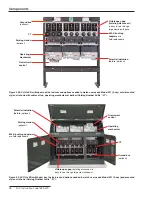

Components

S&C Vista SD Underground Distribution Switchgear features load-interrupter switches and

microprocessor-controlled fault interrupters for the switching and protection of 600-ampere

main feeders and 200- or 600-ampere taps, laterals, and sub-loops. These elbow-connected

components are encapsulated in an environmentally friendly solid-dielectric insulating

material. Vista SD switchgear is available in ratings through 29 kV and 16 kA symmetrical

interrupting. See Figures 4 and 5 on pages 10 and 11.

S&C Vista SD Underground Distribution Switchgear is considerably smaller than traditional

air-insulated gear; it can be installed exactly where it’s needed. It’s completely submersible

and thus suitable for installation in subsurface vaults subject to flooding. Single-way Vista

SD assemblies are ideally suited for application on the primary side of network transformers.

Multi-way assemblies—from three to six load-interrupter switches or fault interrupters—are

also available.

S&C Visi-Gap load-interrupter switches use a vacuum interrupter in series with a manually

operated two-position isolating disconnect for three-pole live switching of 600-ampere three-

phase circuits. Load-interrupter switches comply with IEEE Standard 1247 and IEC Standard

62271-103. They feature an easy-to-operate manual operating mechanism.

S&C Visi-Gap fault interrupters use a vacuum interrupter in series with a manually operated

two-position isolating disconnect for three-pole load switching of 200- or 600-ampere circuits

and fault interrupting through 16 kA symmetrical at 17.5 kV and through 12.5 kA symmetrical at

29 kV. Fault interrupters comply with both IEEE Standard C37.60 and IEC Standard 62271-111.

Load-interrupter switches and fault interrupters can be directly opened and closed

using the manual handle furnished; they can also be operated remotely using a piece

of rope attached to the manual handle or by a user-furnished universal pole of the

appropriate length, equipped with a standard fitting. Opening and closing speed of the vacuum

interrupters is not dependent upon the speed with which the handle is moved. Operating shafts

are padlockable in either position.

Factory-installed and wired motor operators, to facilitate remote power operation

of load-interrupter switches and fault interrupters, are optionally available. They can

be decoupled from the operating mechanisms to permit testing without changing the

positions of the switches or fault interrupters. The motor operators require a user-furnished 100-

240 Vac 50/60-Hz control power source; they’re controlled from a hand-held, cable-connected

portable remote control pendant.

Easy-to-follow mimic bus and indicators on the front of the switchgear convey the positions

of the load-interrupter switches and fault interrupters (and their isolating disconnects), and

whether a fault interrupter has tripped on a fault. The default color scheme is green for the

OPEN/RESET indicator and red for the CLOSED indicator. These colors will be reversed (i.e.,

green for the CLOSED indicator and red for the OPEN/RESET indicator) if catalog number

sffix “-J1” has been specified.

Large viewing windows provide a clear view of the isolating disconnects, allowing operating

personnel to easily confirm the positions of the load-interrupter switches and fault interrupters.

Terminals are equipped with field-replaceable 600-ampere rated bushing adapters. Fault

interrupters may be optionally equipped with 200-ampere bushing-well adapters in lieu of

600-ampere bushing adapters. Bushing and bushing-well adapter interfaces conform to IEEE

Standard 386 and accept all standard insulated connectors and inserts recognized by this

standard.

The self-powered overcurrent control can be programmed using a personal computer

connected to the control through an adapter cable. The control features a variety of fuse

and relay time-current characteristic (TCC) curves that comply with IEEE Standard C37.112.