17

3. Replace the electrical connection label existing in the back side of the electrical terminal box with the one symmetri-

cal label supplied in the accessory bag.

4. Only in cold climates where by-pass is used as part of the defrost strategy of the heat exchanger: Reverse the direc-

tion of the by-pass so that it remains at the supply of the unit.

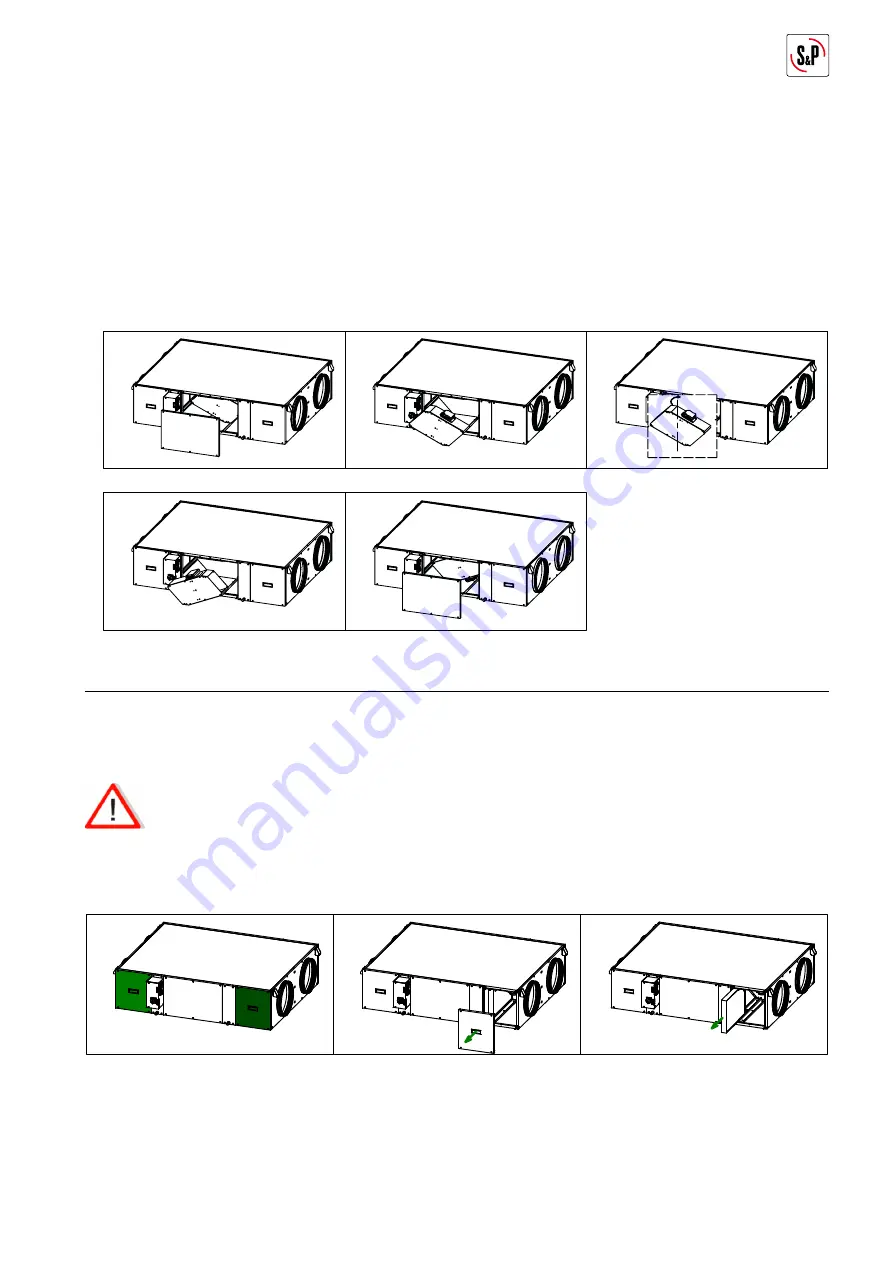

1. Disconnect the heat recovery unit.

2. Remove the side panel (fig.1).

3. Extract carefully the bypass (fig.2).

4. Disconnect the electrical connector that feeds the bypass.

5. Turn the bypass according to image (fig.3 and 4).

6. Reconnect the electrical power connector of bypass.

7. Place the bypass in its housing again (fig.5), close the panel and start up the unit.

Fig.1

Fig.2

Fig.3

5

.

g

i

F

4

.

g

i

F

180º

7. INSPECTION, MAINTENANCE AND CLEANING

7.1. FILTERS REPLACEMENT

The registers ubication for filters maintenance depends on the model and version. The exact ubication of the filters is

identified by a label in the profile that indicates the type of filter and its characteristics.

FALLING OBJECTS

By loosening the screws that hold the panels, they will be released. In units installed in ceiling, pay spe-

cial attention to this operation to prevent the fall of a panel. During the maintenance signaling the area

below the heat recovery unit and prevent personnel access to it.

Access to filters is done by removing the two registration panels located on the side of the heat recovery unit. To replace

the filters, follow the following sequence:

Fig.3

Fig.2

Fig.1

1. Access to the filters is done by removing the two existing side panels on the side where the electrical cabinet is located

(Fig.1).

2. Remove the 4 screws that fix the filter access panel. Hold the panel preventing it from falling when loosening the last

screw. (Fig 2).

3. Pull the dirty filter outwards, sliding it on the existing guide.

In the process of assembling the new filter, follow the reverse order, paying attention to the arrow that defines the direc-

tion of the air that you will find in the new S&P filter.

Summary of Contents for CAD-COMPACT 500

Page 1: ...EN CAD COMPACT ECOWATT...