s30nmdl3sm-rev1218

sandpiperpump

.

com

Model S30 Non-Metallic •

18

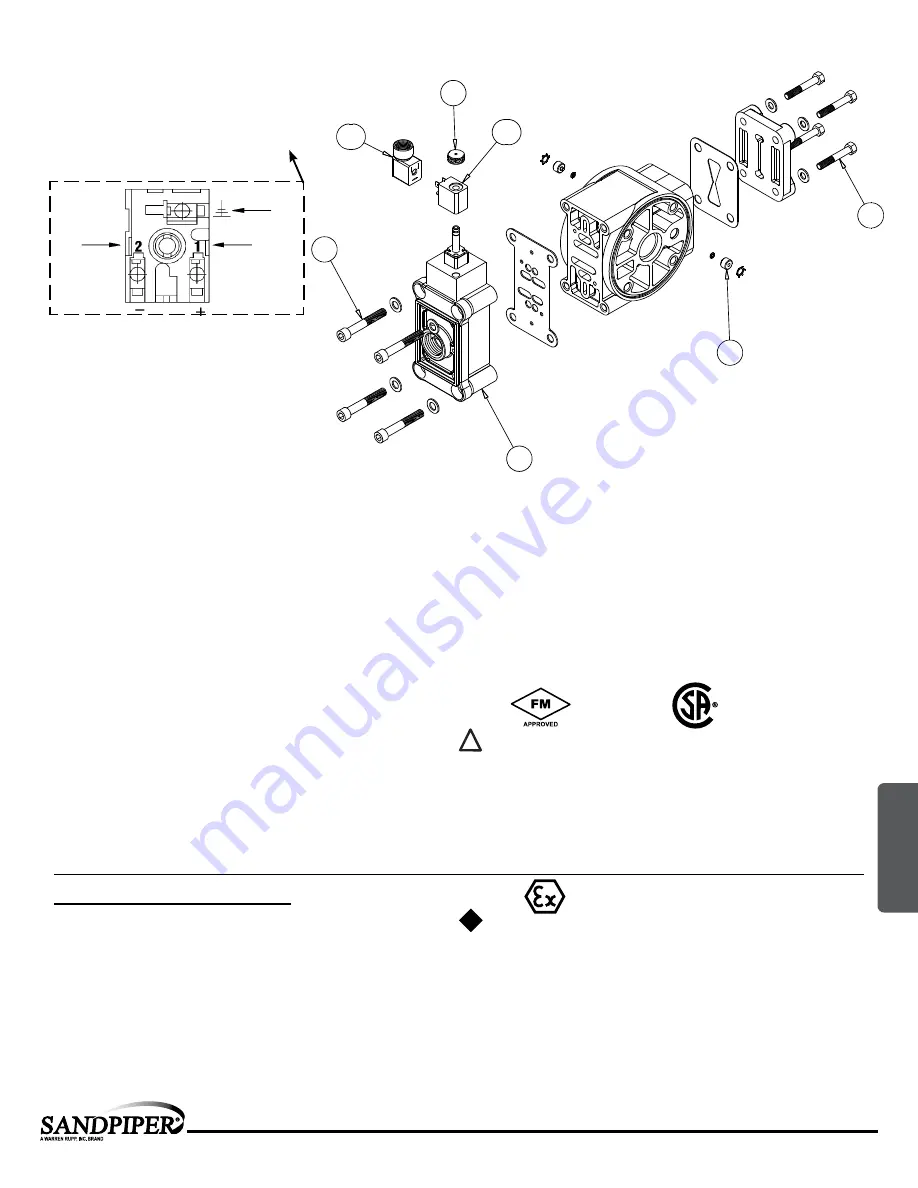

Solenoid Shifted Air Valve

Solenoid Shifted Operation

The Solenoid Shifted pump has a solenoid operated, air distribution valve in

place of the standard pilot operated, air distribution valve. Where a pilot valve

is normally utilized to cycle the pump’s air distribution valve, an electric solenoid

is utilized. The solenoid coil is connected to a customer-supplied control. As the

solenoid is powered, one of the pump’s air chambers is pressurized while the

other chamber is exhausted. When electric power is turned off, the solenoid

shifts and the pressurized chamber is exhausted while the other chamber

is pressurized. By alternately applying and removing power to the solenoid,

the pump cycles much like a standard pump, with one exception. This option

provides a way to precisely control and monitor pump speed.

Before Installation

BEFORE WIRING THE SOLENOID

, make certain it is compatible with your

system voltage.

#2 Terminal

Neutral

(Negative)

#1 Terminal

Power

(Positive)

3rd Terminal

for ground.

Wiring

Diagram

58

56

57

56

60

59

61

Solenoid Shifted Air Valve Parts List

(Includes All Items Used on Composite Repair Parts List

Except as Shown)

Item

Part Number

Description

Qty

56

893.097.000

Solenoid Valve, NEMA4 1

57

219.001.000

Solenoid Coil, 24VDC

1

219.004.000

Solenoid Coil, 24VAC/12VDC

1

219.002.000

Solenoid Coil, 120VAC

1

219.003.000

Solenoid Coil, 240VAC

1

58

241.001.000

Connector, Conduit

1

59

170.029.330

Capscrew, Hex HD 5/16-18 x 1.50

4

60

618.051.150

Plug

2

61

171.053.330

Capscrew, Socket Head

4

IEC EEX m T4

For Explosion Proof Solenoid Coils used in North America and

outside the European Union.

57

219.009.001

Solenoid Coil, 120VAC 60 Hz

1

219.009.002

Solenoid Coil, 240VAC 60 Hz

1

219.009.003

Solenoid Coil, 12VDC

1

219.009.004

Solenoid Coil, 24VDC

1

219.009.005

Solenoid Coil, 110VAC 50 Hz

1

219.009-006

Solenoid Coil, 230VAC 50 Hz

1

Note: Item 58 (Conduit Connector) is not required

For Explosion Proof Solenoid Coils used in the European Union

*Special Conditions For Safe Use

A fuse corresponding to its rated current (max. 3*I

rat

according IEC 60127-2-

1) or a motor protecting switch with short-circuit and thermal instantaneous

tripping (set to rated current) shall be connected in series to each solenoid

as short circuit protection. For very low rated currents of the solenoid the

fuse of lowest current value according to the indicated IEC standard will be

sufficient. The fuse may be accommodated in the associated supply unit or

shall be separately arranged. The rated voltage to the fuse shall be equal

to or greater than the stated rated voltage of the magnet coil. The breakage

capacity of the fuse-link shall be as high as or higher than the

maximum expected short circuit current at the location of the

installation (usually 1500 A). A maximum permissible ripple of 20% is valid for

all magnets of direct-current design.

For ATEX Compliant Solenoid Coils used in the European Union

57

219.011.001 Solenoid Coil, Single mounting

12 VDC, 3.3W / 267mA

1

219.011.002 Solenoid Coil, Single mounting

24 VDC, 3.3W / 136mA

1

219.011.003 Solenoid Coil, Single mounting

110/120 VAC, 3.4W / 29mA

1

219.011.004 Solenoid Coil, Single mounting

220/240 VAC, 3.4W / 15mA

1

Note: Item 37 (Conduit Connector) is not required

*

II 2G EEx m c T5

II 2D c IP65 T100°C

II 2G EEx m c II T5

II 3/2 G Ex m c II T5

II 2D c IP65 T100°C

Compressed Air Temperature Range:

Maximum Ambient Temperature

to plus 50°C

6: OPTIONAL