CAUTION - Failure to observe the above may result in

engine damage not covered under warranty.

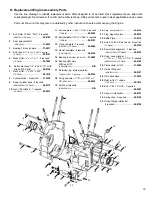

1.

Crankcase preparation before assembly.

NOTES - S&S crankcases are sold in matched sets only.

Individual case halves are not available.

S&S Twin Cam style engines are shipped with cylinder

studs installed Before assembling engine, verify that the

lower collar of each stud is contacting the case deck, and

that the studs are torqued to 10 ft.-lbs.

1.

Disassemble crankcases & wash in hot, soapy

water. Rinse case halves and blow dry with

compressed air. Check all internal passages. Coat

bearing surfaces with a light oil to prevent rust.

2.

Install pinion bearing into right side case half.

See Picture E1.

a. Lubricate outer race of pinion bearing and

crankcase pinion bearing bore.

b.

Using a suitable arbor, press pinion

bearing into bore so that it is centered

between the two snap ring grooves.

CAUTION - press only on outer race of bearing. Do not

press on inner race, bearing damage will occur.

c. Install snap ring into groove on each side

of bearing.

NOTE - If one side of the snap ring has a sharp corner and

one edge is rounded, install the ring with the sharp corner

facing out from the bearing

3. Install piston oilers into right-side crankcase.

a.

Lubricate o-ring with engine oil and install

in piston oiler.

b.

Apply Loctite 243 to screws. Install oilers,

tighten screws to 25 in-lbs. See Picture E2.

4. Install two case alignment dowels and o-rings

into right side crankcase.

NOTE - O-rings must be installed. O-rings that are missing

or damaged will cause oil leakage.

2.

Install flywheels in crankcase.

1. Thoroughly clean parts according to

instructions previously mentioned. Apply coat

of assembly lube to bearing surfaces.

2

Place flywheel assembly onto a suitable

holding fixture, with sprocket shaft pointing up.

See Picture E3.

3. Install case and Timken bearing onto shaft with

appropriate tool. See Picture E4.

NOTE - Do not use a press to install sprocket shaft

bearings, as this can push flywheels out of true. Correct

bearing installation tools are available from Harley-

Davidson, Jim’s Machine, and other sources.

4. Place left side crankcase half over sprocket

shaft and onto bearing, insuring that

connecting rods are in correct positions.

See Picture E5.

5. Install included Timken bearing spacer.

See Picture E6.

6. Lubricate rollers of remaining Timken bearing

with assembly lube. Apply assembly lube to

bearing inner race and sprocket shaft bearing

surface.

7. Install bearing on shaft with appropriate tool.

See Picture E7.

8. Place assembled left case half and flywheel

assembly onto a suitable holding fixture, with

pinion shaft pointing up.

9 Lubricate pinion bearing and pinion shaft inner

bearing race with assembly lube.

3. Assemble crankcase halves

1. Install baffle plate in bottom of left side case.

Secure with two screws and blue Loctite.

See Picture E8.

2. Wipe down mating surfaces of crankcase

halves with lacquer thinner. Remove residue

with clean, dry cloth, then apply sealant to

both crankcase halves. Take care to avoid

areas where sealant might reach inside of

engine. If applicable, allow sealant to cure

according to manufacturer’s instructions

See Picture E9.

NOTE - S&S uses Threebond 1104 to seal crankcase.

Use any sealant carefully to prevent excess from entering

engine and obstructing oil passages or contaminating oil

supply.

7