6

6-

Remove cover plate that was shipped on

crankcase from the bottom surface of the rear

motor mount. The oil line block will be installed

in this location. Assemble the oil line block by

installing the 90-degree fitting (S&S PN 50-8288)

and the oil return fitting (S&S PN 50-0451) with

O-ring (S&S PN 50-8008) into the block, as shown

in

Picture 3

.

7-

Mount the oil line block on the crankcase using

5

⁄

16

-

18 x 1

3

⁄

4

” long screw (S&S PN 50-0437)—do not final

tighten as it will be removed again.

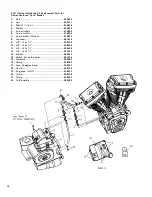

8-

The next step is to measure and then cut the oil

hoses. The straight hose connects the 90 degree

fittings of the oil line block and oil pan. The bent

hose runs between the oil return fittings on the oil

line block and oil pan.

See PIcture 4.

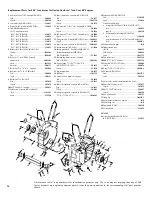

9-

Remove the oil line block from the engine case.

Install the supplied clamps (S&S PN 50-8156) on the

lines between the fittings.

See Picture 5.

10- Install O-Rings (S&S PN 50-8066) in the counter

bores of the oil line block. Position the oil line block

on the engine case and tighten the screw to 18 ft-

lbs. of torque with blue threadlock on the threads.

See Picture 6.

11- Position hose clamps over the fittings.

12- Refill oil reservoir.

13- Start engine and check for oil leaks.

Picture 3

Picture 5

Picture 6

Picture 4

Supply

Return