NOTE - S&S

®

Cycle recommends the use of Harley-Davidson

®

oil

filters, part numbers 63805-80A (black), or 63796-77A

(chrome),or equivalent. The use of an oil filter designed for a

Twin Cam 88

®

is

NOT

recommended.

All reference to Harley-Davidson

®

part numbers is for

identification purposes only. We in no way are implying that any

of S&S

®

Cycle’s products are original equipment parts or that they

are equivalent to the corresponding Harley-Davidson

®

part

number shown.

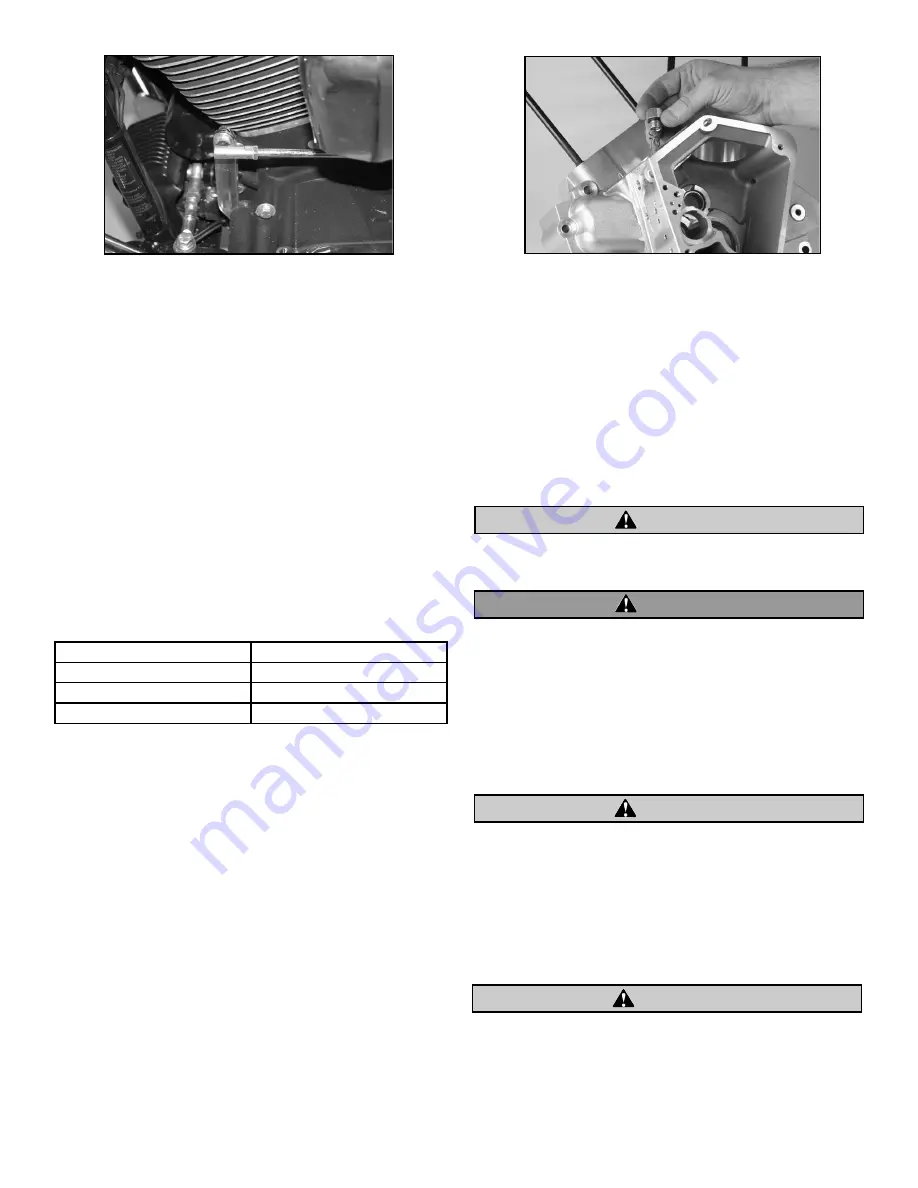

3.

Locate and install oil tank vent hose to fitting above the oil

pump on crankcase.

See Picture 36.

4.

Verify location of oil pump feed fitting on the pump cover

and install oil supply hose from oil tank.

See Picture 37.

5.

Fill the oil tank to the proper level.

NOTE - S&S Cycle recommends the use of Mobil

®

1 V-Twin

20W-50 synthetic oil in our engines. If not using Mobil 1, see

the chart below.

FINAL ASSEMBLY

1.

Refer to service manual for installation of foot rest

assemblies if removed for engine replacement.

2.

Reassemble transmission shift linkage if necessary.

NOTE - On certain models it may be necessary to switch the shift

linkage to the outside of the shift lever.

See Picture 38.

Make

certain that there is clearance between the shifter rod and the

engine crankcases.

3.

Reinstall and connect the fuel tank. Refer to appropriate

service manual. Inspect fuel lines and clamps - replace as

necessary.

a.

Check fuel line connections and routing. Avoid hot

surfaces. Make certain that the protective cover has

been placed over fuel line, and that it is clear from sharp

edges and abrasive surfaces.

b.

Reassemble components that were removed or

disassembled for installation. Consult authorized Harley-

Davidson

®

service manual for installation procedure for

stock parts not covered in S&S instructions.

c.

Check fuel needle and seat assembly. Fill gas tank with

just enough fuel to test system. Lean motorcycle over

towards carburetor side, turn on fuel petcock and wait

20 seconds. If gas runs out end of carb or out overflow

hose, turn off petcock and check needle and seat.

d.

Check fuel inlet fitting and fuel line connections for

leaks. Hose clamps must be tight.

NOTE - Fuel needle and seat assembly must completely shut off

fuel supply to carburetor bowl. Fuel inlet fittings and fuel line

connections must not leak.

Gasoline leaking past inlet needle may flood engine causing

contamination of oil supply and damage to engine.

Any gasoline leak represents a health and fire hazard.

INITIAL START-UP

1.

Remove tappet screen plug and screen assembly from

crankcase.

See Picture 39.

2.

Remove wires from spark plugs. Ground plug wires to

cylinder head with either a jumper wire or through a

test plug.

It is possible to damage certain types of electronic ignitions if

the high-tension side of the ignition coil is left open. Always

ground the spark plug-side of ignition coil when turning

engine over.

3.

Engage manual compression release, if applicable.

4.

Turn ignition on and turn the engine over with the starter

motor until you get engine oil at the tappet screen port.

Avoid excessive time of starter engagement. Overheating of

starter motor will result in damage. After 30 seconds of

continuous starter running, allow 5 minutes for the starter

motor to cool.

17

Picture 38

Picture 39

Viscosity

Ambient Temperature (˚F)

SAE 20W50

Above 20˚ - 100˚

SAE 50

Above 60˚ - 100˚

SAE 60

Above 80˚ - 100˚

CAUTION

WARNING

CAUTION

CAUTION