15

Installation

• This appliance must be installed and serviced only by a suitably qualified and Gas Safe

Registered engineer, and in accordance with the current editions of the following standards

and regulations or other locally applicable regulations:

Gas Safety (Installation and Use) Regulations

Building Regulations

British Standards (BS 5440, BS 6172 and BS 6891)

Regulations for Electrical Installation (BS 7671, (Latest Edition))

• Please, ensure that, once the hob is installed, it is easily accessible for the engineer in the

event of a breakdown

• This hob uses and is ready to use NATURAL GAS only and cannot be used with any other

gas without modification. This appliance is manufactured for conversion to LPG after fitting

new injectors and making adjustments. Refer to “replacement of burner injectors” section

for details.

• Prior to installation, ensure that the local distribution conditions (nature of gas and pressure) and

the adjustment of the product are compatible. The adjustment conditions for this product are stated

on the data plate.

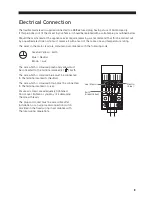

• Ensure that there is a mains socket within reach of the hob cable (1500 mm from the rear left of the

product). This must be accessible after installation or an all-pole disconnection switch must be

provided in the fixed wiring in accordance with the local wiring regulations. The mains cable must

not touch any hot parts.

• Ensure that your kitchen worktop is designed for use in a kitchen.

Ventilation

• This appliance is not connected to a combustion products evacuation device. It should be installed

and connected in accordance with current installation regulations. Particular attention should be

given to the relevant requirements regarding ventilation.

• The appliance should be installed in a room or space with an air supply in accordance with the latest

edition of BS5440-2.

• For rooms with a volume of less than 5m

3

— permanent ventilation of 100cm

2

free area will be required.

• For rooms with a volume of between 5m

3

and 10m

3

a permanent ventilation of 50cm

2

free area will

be required unless the room has a door which opens directly to the outside air in which case no

permanent ventilation is required.

• For rooms with a volume greater than 10m

3

— no permanent ventilation is required.

• Regardless of room size, all rooms containing the appliance must have direct access

to the outside air via a window that opens or equivalent.

• Where there are other fuel burning appliances in the same room, the latest edition

of BS 5440-2 should be consulted to determine the correct amount of free area

ventilation requirements.

Summary of Contents for S5GONGB13

Page 1: ...Instruction Manual 5 Burner Gas Hob S5GONGW13 S5GONGB13...

Page 23: ......