IMPORTANT PLEASE READ

All products manufactured and supplied by BAGNODESIGN are fit for purpose as long

as they are Installed, used correctly, cleaned and receive regular maintenance in

accordance with these instructions ...

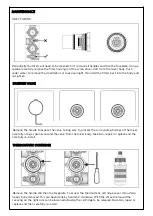

Remove all packaging and check the product for damage or missing parts before commencing

with the installation.

Any alterations made to this product and its components may infringe product certification,

infringe water regulations and invalidate the guarantee. The Installation must comply with all

local/national water supply authority regulations/bylaws and building and plumbing

regulations, therefore we strongly recommend that your product be installed by a reputable

qualified trade's person.

PRODUCT LIFECYCLE

"The product LiveCycle/e is the collective stages that a product goes through from

its

conception

and design through to its ultimate disposal."

DISPOSAL GUIDANCE

The best way to ensure your Product has a long life is to follow the Care and Maintenance guides

set by the Manufacture after purchase. This document can be found at

www.bagnodesignlondon.com.

The life cycle of the product is

not

in correlation to the

product Guarantee; the standards the products are manufactured or certified to (e.g. CE &

WRAS) can exceed past the Guarantee duration. After the life cycle of the product is deemed

complete by the end-user please follow the below to dispose of the items correctly ...

Mixers (Shower Valves):

If the mixers are no longer accepted due to mechanical use or aesthetic style, these can be

disposed of at a registered Local Authority waste recycling center where the individual

components can be sorted.

CLEANING CARE GUIDE

Only use a mild soap and water for cleaning.

Rinse with water to remove the mild soap solution.

We recommend the product is dried using a soft cloth after

every use.

Never

use any abrasive or strong cleaning products containing,

bleaches, acids (hydrochloric, formic, phosphorus, chlorine or

acetic), strong detergents, limescale remover, alcohol or dyes

etc.

Never

use abrasive cleaning pads, wire wool or microfibre

cloths.

Never

use cleaning equipment that may have been pre-

used and contaminated with the above substances.

Never

apply the cleaning product directly onto the finished

surface.

��

��

��

Summary of Contents for KOY

Page 1: ...KOY ZEPHYR THERMOSTATIC SHOWER MIXER www sanipexgroup com ...

Page 2: ......

Page 4: ... ...

Page 14: ...Note ...

Page 15: ...Note ...

Page 16: ...INM KOY ZEP THERMO_MIXER 08 21 www sanipexgroup com ...