Initial adjustments have been performed at the factory.

However, to satisfy individual product preferences, the

following adjustments may be required:

1. Remove power, then remove the right side panel

(guard) as viewed from the front of the machine.

2. Using a regular straight flat blade screwdriver, turn

the mechanical consistency (torque adjustment) screw

(Fig. 22) clockwise to make the product harder or

counterclockwise to make the product softer. Do not

adjust more than one turn each time.

Do not attempt to adjust the belt idler screw marked

“Do Not Adjust”.

EXTREME CARE SHOULD BE EXERCISED TO KEEP

HANDS AND TOOLS AWAY FROM MOVING PARTS.

PERSONAL INJURY COULD RESULT.

WARNING: Adjustments to the mechanical consistency control system should be made ONLY by trained service

personnel. Power must be removed from the machine before panels (guards) or protective covers are removed.

Once the panels (guards) are removed, an adjustment is made, protective panels (guards) are replaced, power is

restored to the machine, and the consistency setting is tested. This process is repeated as necessary until the

desired product consistency is obtained.

The mechanical control system is a very simple method of controlling the consistency of the finished product. The machine

operates without a temperature control. Refrigeration is controlled by measuring the torque on the dasher motor and the

consistency of the product. The tension of a spring against the torque idler determines the consistency of the product.

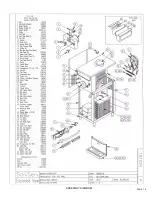

Fig. 22

Mechanical Consistency

Control

CONSISTENCY ADJUSTMENT

Consistency Adjustment

PAGE 12

3. Replace the side panel (guard), restore power, and

start the machine. Wait 10 - 15 minutes or until the

compressor cycles off, then check the consistency of

the product.

4. Repeat steps 1, 2 and 3 until the desired product

consistency is obtained.

WARNING

CAUTION

Summary of Contents for A7081HEP

Page 2: ......

Page 17: ...PAGE 16 ASSEMBLY DIAGRAM ...

Page 18: ...Notes ...

Page 19: ...Service Log ...