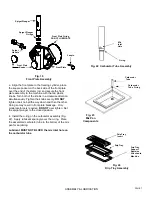

e. Insert the dasher assembly into the freezing cylinder

as far as possible (Fig. 15) being careful not to damage

the scraper blades. Damage will occur to the scraper

blades and the dispenser will not operate properly if the

scraper blades are installed facing in a clockwise

direction (Fig. 16).

Fig. 15

Dasher Installation

Fig. 16

Dasher Installation

Note: The stator rod has been deleted from Fig. 15

and Fig. 16 for clarity only. They must be installed

for proper machine operation.

f. While maintaining force against the dasher, rotate it

slowly until the tongue of the dasher engages the

groove in the drive system at the rear of the cylinder.

The outer most portion of the dasher should be

recessed approximately 1/4” to 3/8” inside the freezing

cylinder. No part of the dasher should extend outside

the cylinder. Scraper blades should be visible (Fig. 17)

extending approximately 1/8” beyond the dasher.

CORRECT

Fig. 17

Dasher with Blade (Front View)

2. Lubricate and assemble the front plate assembly in

the following manner:

a. Install the two o-rings on the spigot plunger by

rolling them onto the plunger. Seat the o-rings in

the grooves. Make certain that they are not twisted.

Smooth the lubricant into the grooves and over

the sides of the plunger assembly (Fig. 18).

Fig. 18

Spigot Plunger Lubrication

b. Slide the lubricated spigot plunger into the front

plate (Fig. 19) Align the spigot handle slot to the front.

c

.

Insert the spigot handle and secure with the faspin.

d. Install the front plate o-ring.

DO NOT LUBRICATE THE FRONT PLATE O-RING

LUBRICANT WILL MAKE THE FRONT PLATE LEAK

ASSEMBLY & LUBRICATION

Lubricate

Shaded Area

Approximately

1/8” Exposed

Blades Should Not Point

In A Clockwise Direction

INCORRECT

PAGE 6

CAUTION

Blades

Resting On Tabs

Blades Pointing In A

Counterclockwise

Direction