1.

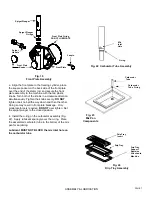

Lubricate and assemble the dasher assembly in the

following manner:

a. Apply a generous amount of lubricant to the shoulder

of the dasher and the area of the shaft where the white

plastic portion of the assembled rear seal contacts the

shaft (Fig. 12). This is easily performed by running a 1/4”

bead of lubricant around the shoulder of the dasher.

b. Lubricate the stator rod (Fig. 12) and slide the stator

rod into the dasher.

C.

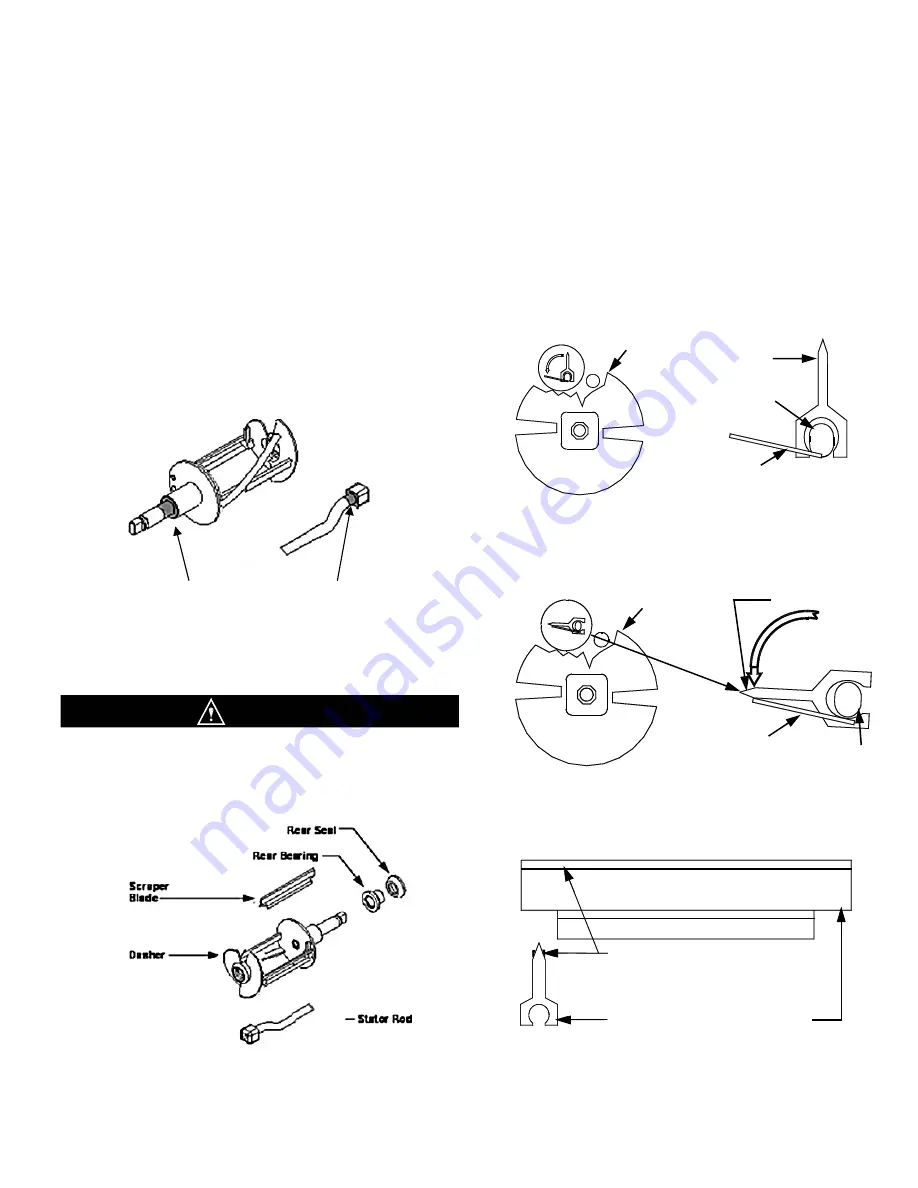

Assemble and install the rear bearing and seal with the

rubber portion toward the rear of the freezing cylinder as

indicated in Fig. 13.

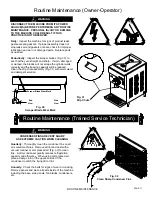

d. Install the scraper blades on the dasher assembly

by holding the blade perpendicular to the tabs

(Fig. 14a) and then snapping them over the flat area of

the support rod. Then rotate the blade downward in a

counterclockwise direction as viewed from the front of

the dasher (Fig. 14b).

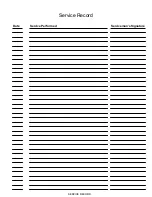

Note:

Reverse the blades at each cleaning to maintain

sharpness. In addition, the blades are equipped

with a wear mark (Fig. 14c). When the blade is

worn to this wear mark, they must be replaced.

Assembly & Lubrication

Use only food approved lubricants. Sanigel (SaniServ part number 188490) is recommended and is available from your

local authorized SaniServ dealer or distributor.

Lubrication must be performed daily.

Blade Support

Tab

Support Rod

Dasher Front View

Scraper Blade

Dasher Front

View

Blade Support

Tab

Support Rod

Scraper Blade

Rotate Down

Counter

Clockwise

Scraper Blade Wear Mark

End

View

Side

View

ASSEMBLY & LUBRICATION

PAGE 5

Fig. 14c

Scraper Blade Wear Mark

Fig. 14a

Scraper Blade Installation

Fig. 14b

Scraper Blade Installation

Fig. 12

Stator Rod and Dasher Lubrication

CAUTION

Fig. 13

Dasher Assembly

DO NOT LUBRICATE THE BACK SIDE OF THE

RUBBER PORTION OF THE SEAL ASSEMBLY.

MACHINE COULD BE DAMAGED.

Lubricate Shaded Areas