3

Grounding Instructions

This appliance must be grounded. If it should malfunction or

breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This

appliance is equipped with a cord having an equipment-

grounding conductor and grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

DANGER

Improper connection of an equipment-grounding conductor

can result in risk of electric shock. Check with a qualified

electrician or service person if you are in doubt as to whether

the outlet is properly grounded. Do not modify the plug provided

with the appliance. If it will not fit the outlet, have proper outlet

installed by a qualified technician.

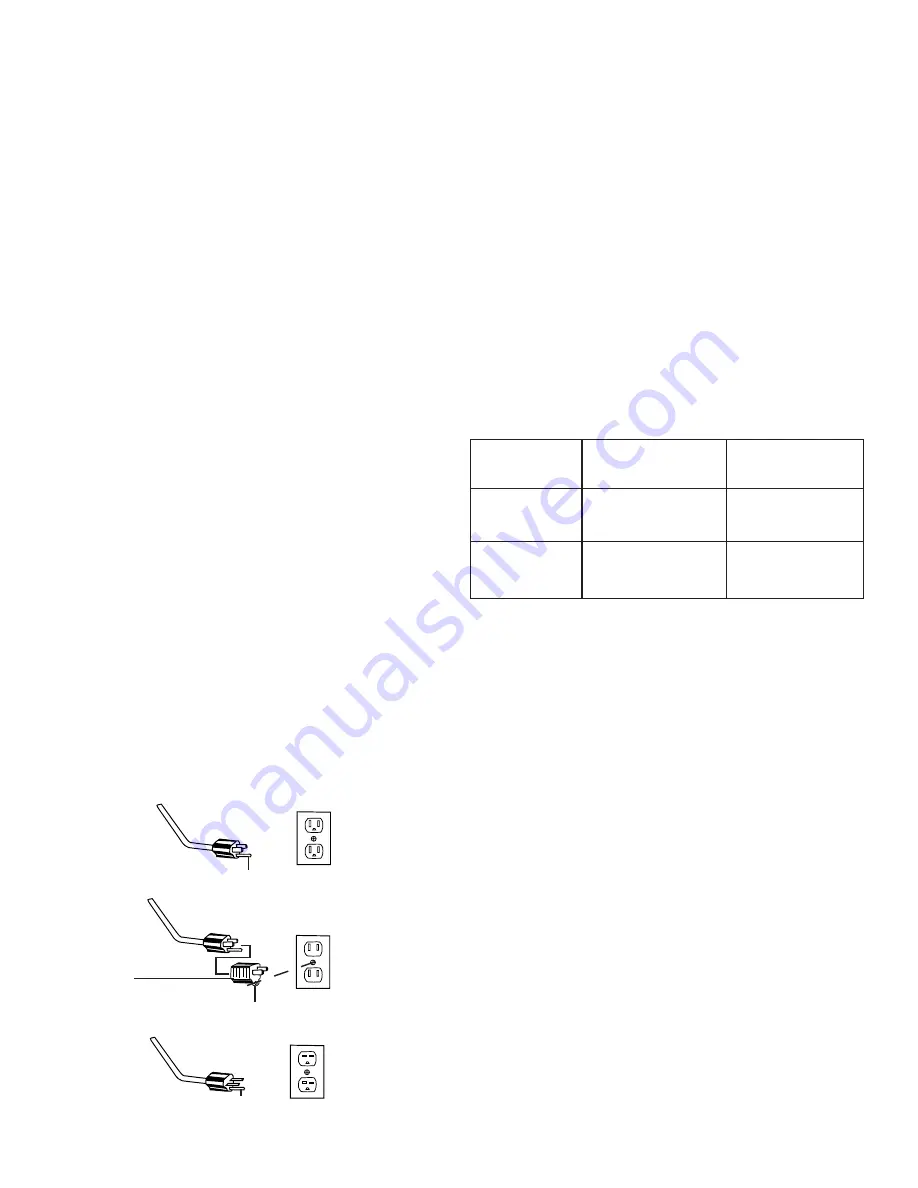

This appliance is for use on a nominal 120 volt circuit and has

a grounding plug that looks like the plug illustrated in Figure

1. A temporary adapter which looks like the adapter illustrated

in Figure 2 may be used to connect this plug to a two-pole

receptacle, as shown, if a properly grounded outlet is not

available. The temporary adapter should be used only until a

properly grounded outlet, Figure 1, can be installed by a

qualified electrician. The green colored rigid ear, lug, or the

like extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box

cover. Whenever the adapter is used, it must be held in place

by a metal screw.

For floor finishing machines rated 150-250 volts:

If the machine is provided with an attachment plug cap as

shown in Fig. 3, it is intended for use on a 240 volt (nominal)

circuit. No adapter is available for this application.

NOTE: In Canada, the use of a temporary adapter is not

permitted by the Canadian Electrical Code.

OPERATION/ACCESSORIES

Choosing the Right Brush and Drive Block

Your floor machine is packed complete and ready for use after

you install a brush or drive block. (Brushes and pads are not

provided with the unit but are available at an additional cost.)

Your floor machine is designed to be used for many different

floor care applications. Make sure you use the correct brush

or pad for the type of job you want to perform. (Accessories

are available from the dealer from whom the floor machine

was purchased.)

MACHINE SIZE

BRUSH DIAMETER

BLOCK DIAMETER

17”

17”

15”

20”

20”

18”

When ordering brushes or drive blocks, refer to this chart and

specify correct brush or block diameter when ordering.

FIGURE 1

FIGURE 2

FIGURE 3

G R O U N D E D

OUTLET BOX

Plug Grounding Pin

Grounding Tab

Metal Screw

Adapter

Plug Grounding Pin