9

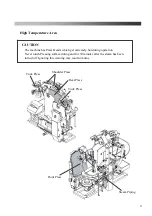

High Temperature Area

CAUTION

The machine has Press Heads which get extremely hot during operation.

Never touch Pressing surface during and for 30 minutes after the steam has been

turned off. Ignoring this warning may result in burns.

Front Press

Shoulder Press

Steam Piping

Tuck Press

Tuck Press

Rear Press

Summary of Contents for LP-570E-V2

Page 54: ...54 Motor Operation Diagram 1 Motor Operation Diagram REV 4...

Page 56: ...56 Air Piping 1 2 Air Piping 1 REV 3 3DLP570E V2 052 2...

Page 58: ...58 Air Piping 2 3 Air Piping 2 REV 3 3DLP550J V2 053 6...

Page 60: ...60 Air Piping 3 4 Air Piping 3 REV 3 3DLP550J V2 054 6...

Page 62: ...62 Steam Piping 5 Steam Piping REV 3 3DLP570E V2 055 1...

Page 64: ...64 Control Box Switch Diagram 6 Control Box Switch Diagram REV 3 3DLP550J V2 056 6...

Page 66: ...66 Cover Diagram 7 Cover Diagram REV 3 3DLP570E V2 057 3...

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ...LP 570E V2X Rev 6 2019 6 1 2 B...