Run the machine where air can be supplied in a stable condition.

Use after-cooler or similar equipment to supply clean air at all times.

Operation Procedures

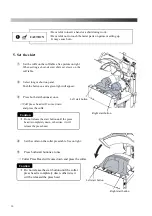

1. Provide Air

The standard air pressure of this machine

is set at 0.6Mpa. Please make sure with

the pressure gauge that the air pressure is

0.6Mpa.

Low air pressure can cause malfunction. If the pressure does not reach its standard level, set

the air pressure properly following the procedure below.

Check Point

Check compressor if the main air pressure does not reach 0.6MPa even after the above

adjustment.

■

How to adjust air pressure

1.

Pull the adjustment knob up

2.

T

urn the knob to adjust air pressure

Clockwise

→

Pressure will increase

Counterclockwise

→

Pressure will decrease

3. Pull the knob down

Follow the procedure for proper operation.

Improper operation can cause mechanical failure or injury to operators.

CAUTION

Pressure Gauge

(0.6Mpa)

Attention

Air Inlet

14

Summary of Contents for LP-660E-V2

Page 2: ......

Page 38: ...36...

Page 39: ...Spare Parts List Index 1 Front Diagram 2 Rear Diagram 3 Steam Piping 4 Cover Diagram 37...

Page 40: ...1 Front Diagram REV 1 38...

Page 44: ...3 Steam Piping REV 1 42...

Page 46: ...4 Cover Diagram REV 1 44...

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......