Summary of Contents for LP-690E-V3

Page 2: ......

Page 11: ...9...

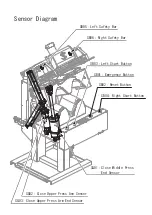

Page 13: ...11 Main Device Main Unit...

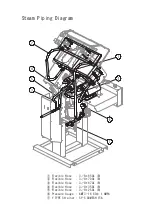

Page 41: ...39 Spare Parts List Index 1 Front Diagram 2 Rear Diagram 3 Steam Piping 4 Cover Diagram...

Page 42: ...40 Front Diagram 1 Front Diagram REV 1 3DLP690J V3 051 1...

Page 44: ...42 Rear Diagram 2 Rear Diagram REV 1 3DLP690J V3 052 1...

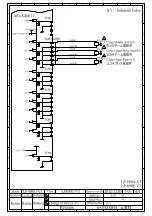

Page 46: ...44 Steam Piping 3 Steam Piping REV 1 3DLP690J V3 053 1...

Page 48: ...46 Cover Diagram 4 Cover Diagram REV 1 3LP690J V3 054 1...

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 57: ......