4.

⇒

adjust the whistling valve by its knurled screw to the re-

quired operating temperature (indicated in the cut-out of the

scale disc), e.g. 3 bar.

⇒

then open the pressure control valve by turning it clock-

wise until the stop point is reached. The autoclave must be

vented during the heating up stage.

⇒

the heating system can then be switched on at full capacity.

B: During operation

WARNING:

Please observe the "Safety Instructions"

and "Acceptable Risks" (Chapters 1. and 1.2), but

particularly the section "During Operation".

1. The autoclave is adequately vented when a strong jet of

steam is being emitted by the pressure control valve (ap-

prox. 100°C thermometer display). Close the pressure con-

trol valve.

2. The acoustic warning signal of the whistling valve indicates

that the required operating pressure has been reached.

Close the whistling valve by turning it to the right until the

stop point is reached. (Please note: The figures of the scale

disc relate to the outgoing connection of the valve).

Only

from this moment onwards does the sterilization time

commence.

WARNING:

Autoclaves without MCS control must

be

constantly

supervised during the sterilization proc-

ess!

The steam pressure control valve may have to be readjusted

to ensure that the operating pressure is not exceeded or un-

dercut (see safety instructions and acceptable risks)!

__________________________________________________

page 17

This Autoclaves are

not permitted for preparation of food.

2.1 Fields of application

WARNING:

High-pressure steam sterilization of po-

rous (e.g. textiles) or packaged products can result in

inadequate sterilization.

IMPORTANT:

The series KL and TKL autoclaves are not ad-

mitted for sterilisation of medical products within the meaning of

the European Guideline 92/42/CCE.

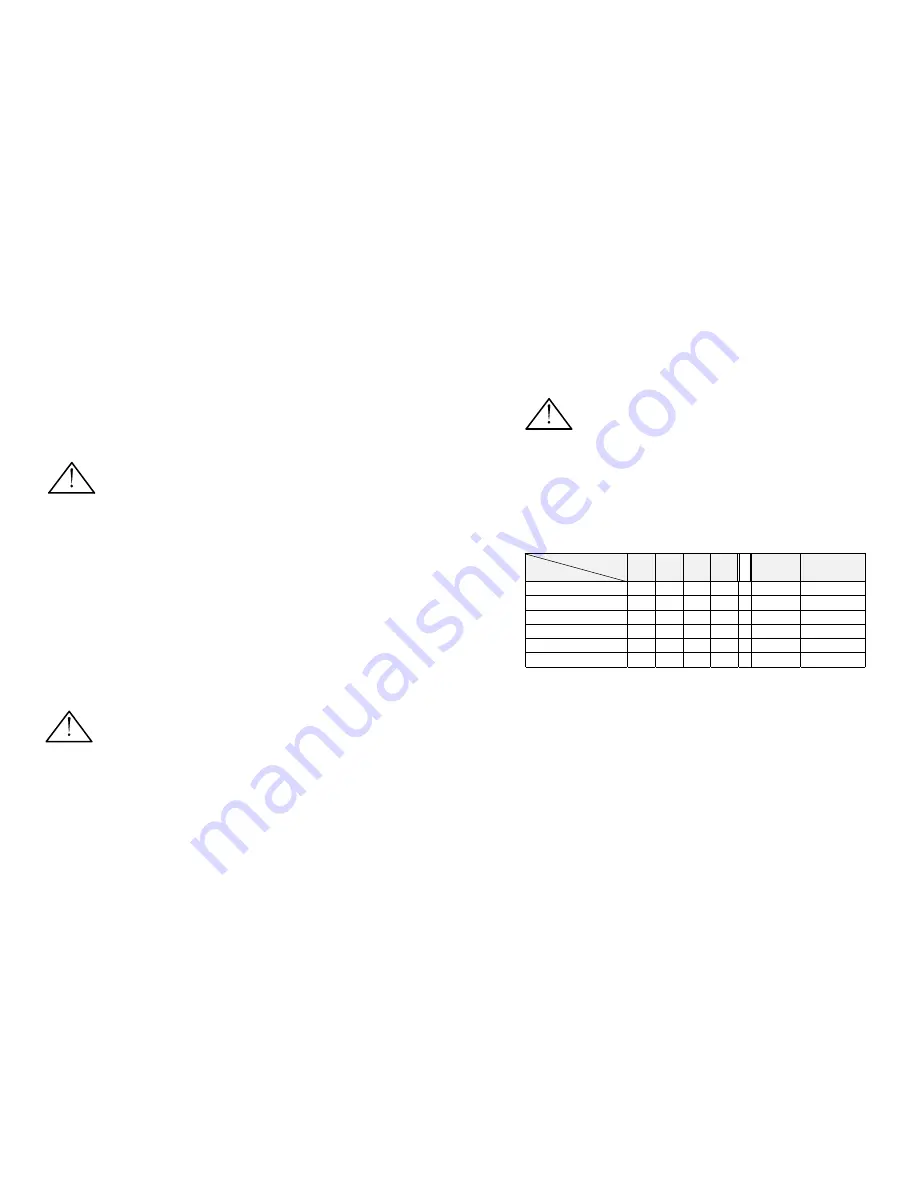

Table 1: Fields of application and technical data

Application

Model

1*

2*

3*

4*

Weight

(kg)

Dimensions

(B x H [x T] in cm)

KL-5-3

x

x

x

x

2,5

35 x 24

KL-7-3

x

x

x

x

2,75

35 x 30

KL-12-2

x

x

x

x

3,7

40 x 34

TKL-MCS-53

x

x

x

x

12,5

35 x 30 x 44

TKL-MCS-73

x

x

x

x

15

36 x 40 x 46

TKL-MCS-122

x

x

x

x

17,7

52 x 43 x 48

1* =

Sterilization of solid substances.

2* =

Sterilization of liquids (in general = e.g. laboratory operation). The

manufacturer recommend the use of special equipment (see Section 4).

3* =

Sterilization in an oil bath.

4* =

Cultivation of nutrient media (laboratory area)

The sterilizers are not permitted for cultivation of nutrient media, which are used

for In-vitro-diagnostics

_____________________________________________________

page 10