Sanosil Q-Jet Advanced

14

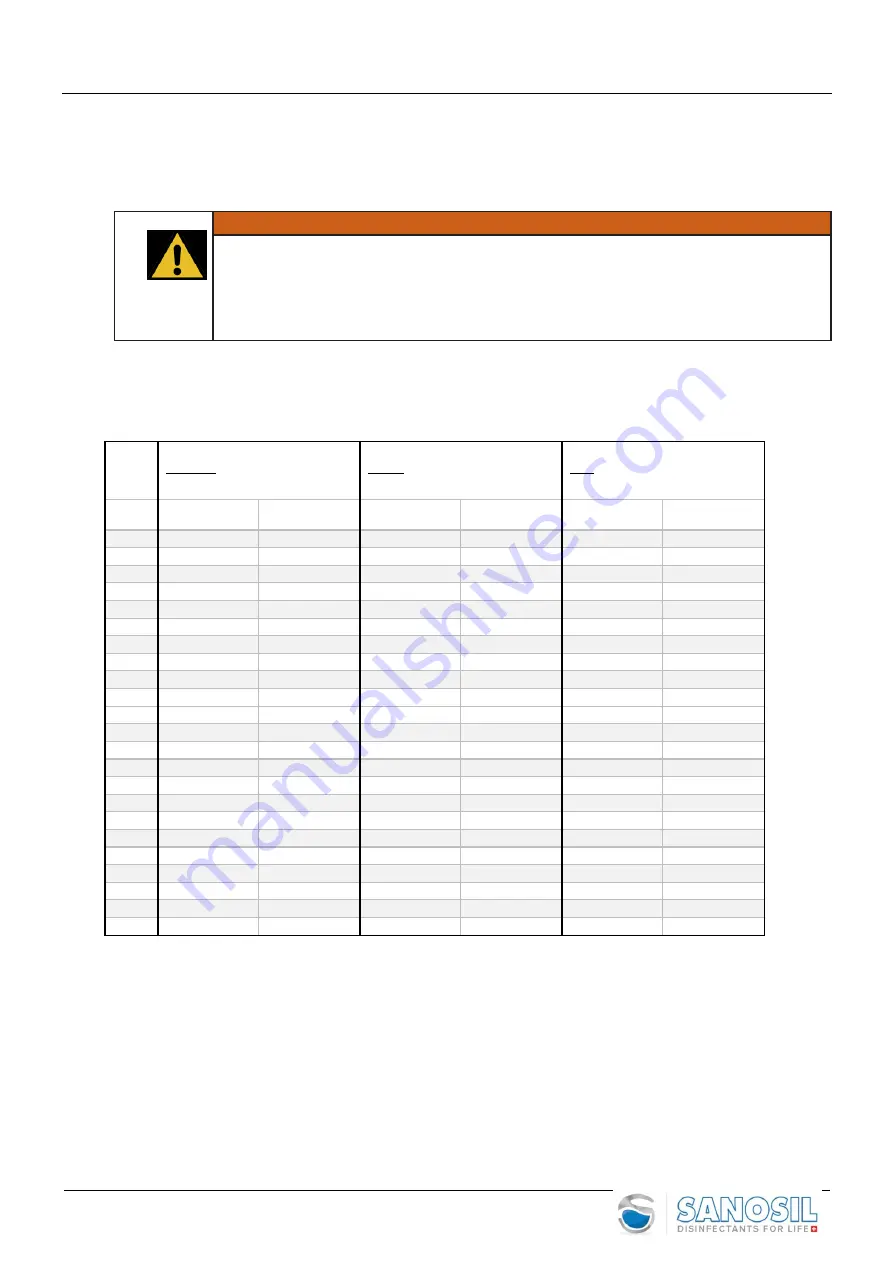

Fogging time and consumption (standard / higher / high contamination)

WARNING

The dosing values below are a recommendation for well pre-cleaned rooms only and are

based on many years of experience and are partly supported by test reports. However, the

values given are not binding as the disinfection effect can be influenced by many factors.

Binding proof of efficacy must be confirmed by microbiological checks after disinfection.

For room treatments according norm Afnor T72-281 (2014) refer to page 18 (5.5 Step).

The below dosage recommendations are not valid for the norm Afnor T72-281 2014

Dosage values for well precleaned rooms

Room

Size

Fogging time/consumption

standard contamination

(8ml/m

3

)

Fogging time/consumtion

higher contamination

(12ml/m

3

)

Fogging time/consumtion

high contamination

(16ml/m

3

)

m

3

time:

Consumption in

ml:

time:

Consumption in

ml:

time:

Consumption in

ml:

10

3 min

99 ml

5 min

165 ml

6 min

198 ml

20

5 min

165 ml

8 min

264 ml

10 min

330 ml

30

7 min

231 ml

7 min

231 ml

14 min

462 ml

40

10 min

330 ml

11 min

363 ml

20 min

660 ml

50

12 min

396 ml

18 min

594 ml

24 min

792 ml

60

15 min

495 ml

23 min

759 ml

30 min

990 ml

70

17 min

561 ml

26 min

858 ml

34 min

1122 ml

80

19 min

627 ml

19 min

957 ml

38 min

1254 ml

90

22 min

726 ml

33 min

1089 ml

44 min

1452 ml

100

24 min

792 ml

24 min

1188 ml

48 min

1584 ml

150

36 min

1188 ml

54 min

1782 ml

72 min

2376 ml

200

48 min

1584 ml

72 min

2376 ml

96 min

3168 ml

250

60 min

1980 ml

90 min

2970 ml

120 min

3960 ml

275

66 min

2210 ml

99 min

3267 ml

132 min

4420 ml

300

73 min

2409 ml

110 min

3630 ml

---

---

350

85 min

2805 ml

128 min

4224 ml

---

---

400

97 min

3201 ml

---

---

---

---

450

109 min

3597 ml

---

---

---

---

500

120 min

3960 ml

---

---

---

---

550

132 min

4356 ml

---

---

---

---

Check temperature of the room, to be between 15 to 35 °C.

Check relative humidity of the room, to be max. 45 % rH. / (before fogging)

at higher humidity, the humidity must be lowered before start-up or a lower dosage of the active substance must be selected.