Sanosil Q-Jet Advanced

25

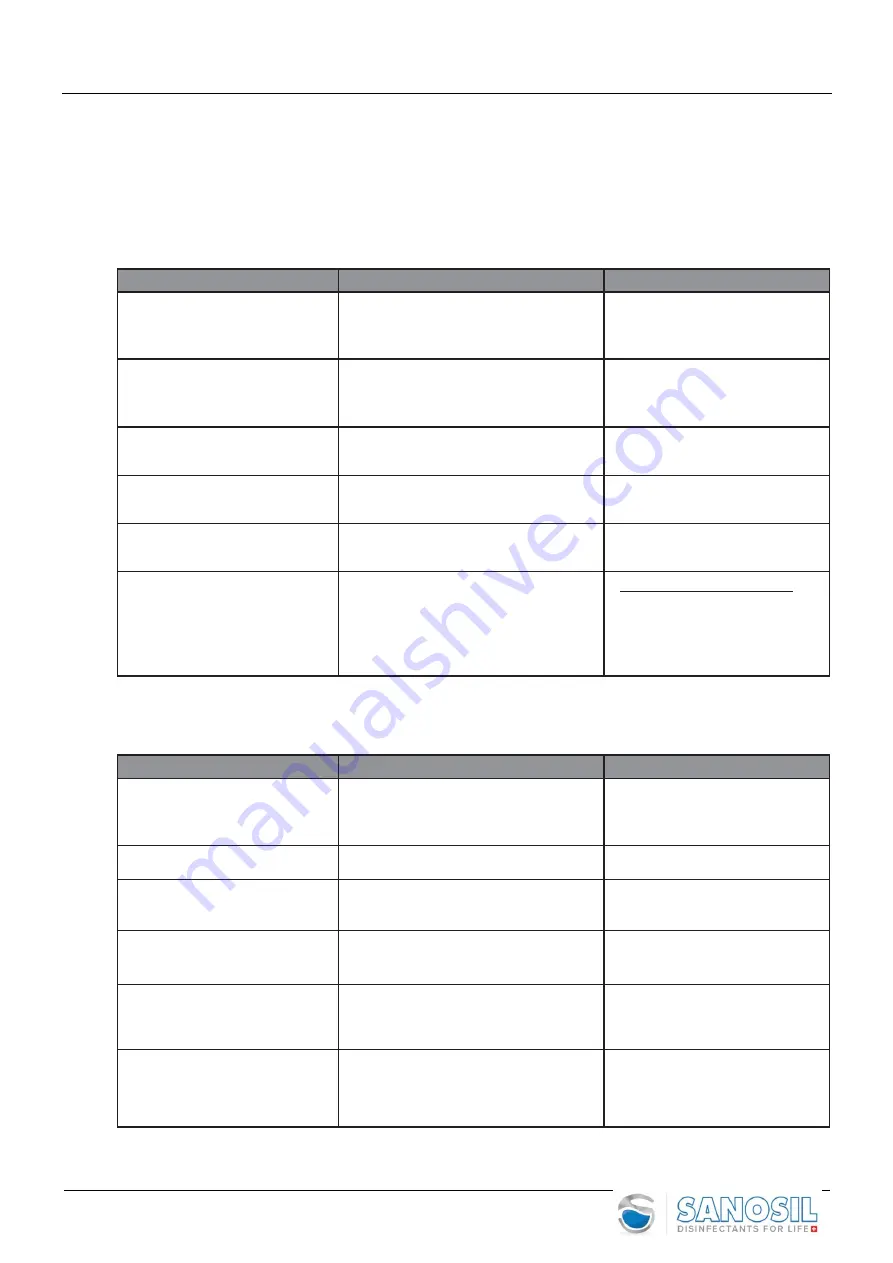

7. Troubleshooting

To determine and search for anomalies it is essential to have this Operation and Maintenance Manual at hand.

7.1 Table

Anomaly

Possible Cause

Remedy

Device does not work / does not

respond

•

Check power supply

•

Check fuses

•

Check correct insertion of cable

•

Ensure power supply to device

Fan does not work

•

Thermal motor sensor stops engine

(too high engine temperature)

•

Air-intake filter too dirty

•

Check engine, switch off and on

•

Set-up device once more

•

Clean or change filter

Liquid is not sprayed

•

Tank is empty

•

Nozzle is clogged

•

Fill liquid

•

Remove obstruction

Device does not start or stops

before finishing program

•

Cycle has been terminated abnormally

(e.g. power cuts)

•

Switch off and on again

•

Set-up device once more

Device emits loud noises

•

Possible internal damages

•

Presence of foreign bodies in the fan

•

Switch off and unplug device, call

service technician

Device leaks liquid

•

Possible internal damages

•

Internal piping rupture or connections

leaking

•

Device was tipped on its side without

completely empty.

•

Switch off and unplug device,

open device and remove water.

Let device completely dry. If

device still leaks call service

technician

7.2 Warning on Display

Warning

Possible Cause

Remedy

LIQUID LEVEL

•

Liquid level monitor determines

too low liquid level. Device stops

(LED flashes).

•

Fill liquid

•

Set-up device once more and start

again

FUSE DEFECT

•

Fuse blown / defect

•

Check / change fuse on print plate

CYCLE INTERRUPTED

•

Automatic cycle has been

interrupted early

•

Switch off and on again

•

Set-up device once more

!!! SERVICE !!!

•

Maximal running time since last

Service has been reached or exceeded

•

Switch off and unplug device, call

service technician

TIMER NOT OK

•

System is in automatic mode but

Timer is not set or activated

•

Check Timer’s

settings

MAX. TIME EXCEEDED

•

Inputted volume (m

3

) and/or

concentration (ml) are too high,

hence calculated time exceeds

device’s

capacities.

•

Check and adapt settings