Sanosil Q-Jet Compact

10

4.

Getting Started and Operating Instructions

4.1 Position

•

Place device on a stable, flat, dust-free, not slippery, horizontal surface which can appropriately support its weight.

•

Point nozzle towards center of the room.

•

Do not point nozzle towards smoke detectors and check with facility management to take appropriate measures that the

former will not be activated during nebulization process

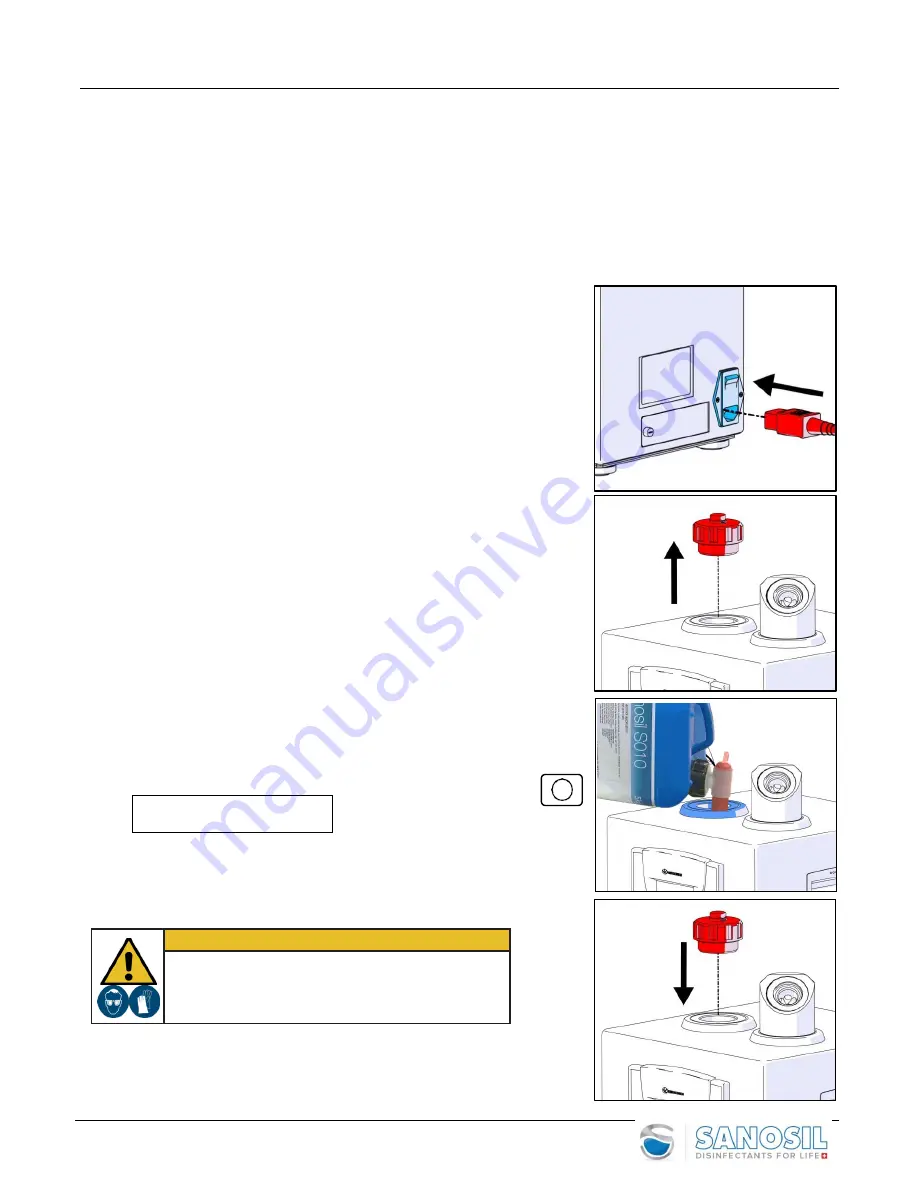

4.2 Power Connection

•

Before making electrical connections carefully check that the

voltage supplied is compatible with the voltage marked on the

data plate.

•

Insert power cord (2) in IEC power socket.

4.3

Filling

•

Remove tank cap (6)

•

Fill disinfection liquid (max. 2,5 Liter!)

The system warns of reaching the max. by an acoustic signal (loud beep)

Liquid level is shown on display with % filling level.

•

Check liquid level on level on display, indicated in % (push I/O button)

Liquid Level

100 %

•

Wipe-up any spills with a microfiber towel or rag

CAUTION

Risk of Injuries!

Always wear gloves and safety googles when filling the

tank!

Do not overfill! This will damage the device.

Wind tank cap (6) until shut

2

6

6

6

i