Sanosil Q-Jet Compact

15

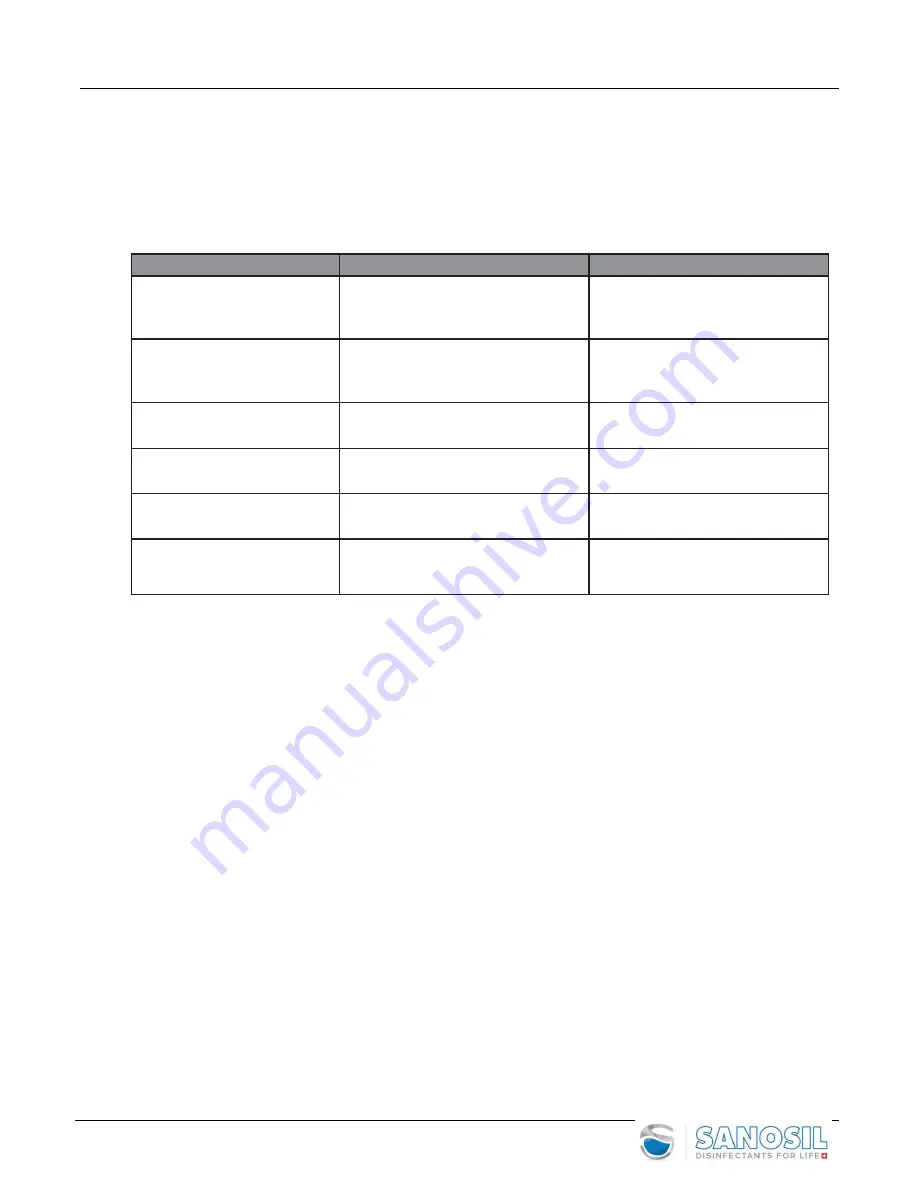

6. Troubleshooting

To determine and search for anomalies it is essential to have this Operation and User Manual at hand.

•

Do not tip the device on its side over 60°at any time unless completely empty and dry.

Anomaly

Possible Cause

Remedy

Device does not work / does not

respond

•

Check power supply

•

Check fuses

•

Check correct insertion of cable

•

Ensure power supply to device

Fan does not work

•

Thermal motor sensor stops engine

(too high engine temperature)

•

Air-intake filter too dirty

•

Check engine, switch off and on

•

Set-up device once more

•

Clean or change filter

Liquid is not sprayed

•

Tank is empty

•

Nozzle is clogged

•

Fill liquid

•

Remove obstruction

Device does not start or stops

before finishing program

•

Cycle has been terminated abnormally

(e.g. power cuts)

•

Switch off and on again

•

Set-up device once more (4.5.2)

Device emits loud noises

•

Possible internal damages

•

Presence of foreign bodies in the fan

•

Switch off and unplug device,

call service technician

Device leaks liquid

•

Possible internal damages

•

Internal piping rupture or connections

leaking

•

Switch off and unplug device,

call service technician