Sanosil Q-Jet Superior

38

7.2

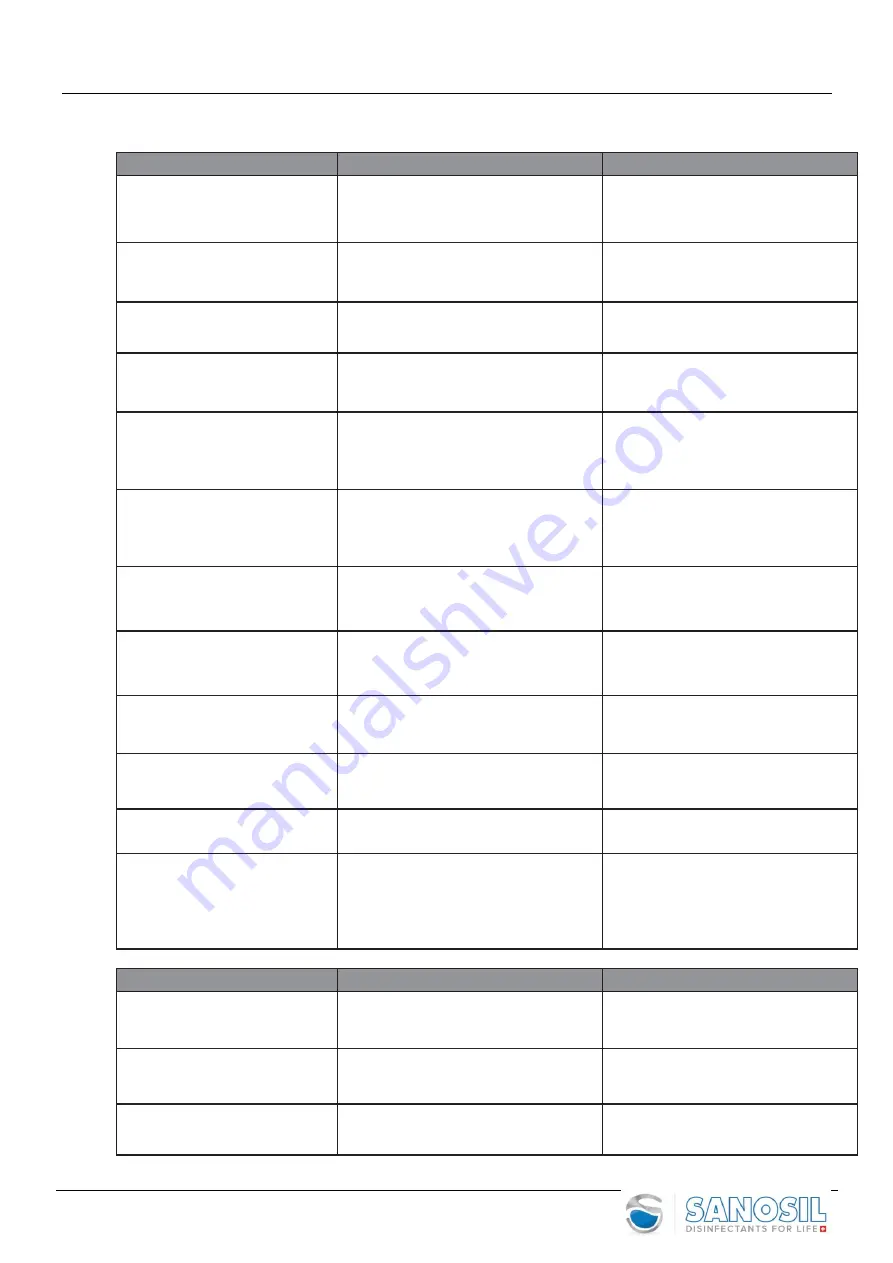

Alarms, Messages and Actions

Alarm

Description

Action

ALR-01 :

LIQUID LEVEL

•

Liquid level monitor determines too low

liquid level. Device stops (LED flashes).

•

Fill liquid

•

Set-up device once more and start

again

ALR-02 :

MOTOR TEMPERATURE

•

Fan engine too hot

•

Switch OFF

–

ON and check permitted

room temperature range

•

Check air-intake and air-intake filter

ALR-03:

TIMER NOT SET

•

System is in automatic mode but Timer

is not set or activated

•

Check Timer’s

settings

ALR-04:

!!! SERVICE !!!

•

Device exceeded maximum number

of hours of operation since last routine

maintenance.

•

Switch off and unplug device, call

service technician

ALR-05 :

HUMIDITY NOT OK

•

Sensor detects too high ambient

humidity during operation,

i.e. above 85%.

•

System stops.

•

Check ambient humidity

•

Switch OFF and ON

ALR-06 :

TEMP. OUT OF RANGE

•

Sensor detects too high or too low

ambient temperature during operation,

i.e. outside permitted range of 5-40°C.

•

System stops.

•

Check ambient temperature

•

Switch OFF and ON

ALR-07:

PRE-ALARM LIQUID LEVEL

•

Low liquid level indication, i.e. less than

10% left in tank

•

None, but preferably fill liquid

(see 4.3)

ALR-08:

SD CARD NOT READY

•

Indication that SD card is

malfunctioning, i.e. SD card is not

formatted or defect

•

Contact Customer Service

ALR-09:

INP. STEP TIME

•

Times for step cycles are not all set

•

Set / correct step-cycles times

ALR-10:

FUSE DEFECT

•

Fuse on print plate (conductor board)

blown / defective

•

Contact professional technician or call

Customer Service

ALR-11:

CONCENTRATION

•

Concentration (dosage) is not or not

correctly set

•

Check on respective menu and set

concentration adequately

ALR-12:

INSUF.LIQUID FOR PROGR.

SELECTED

•

Signals insufficient liquid for running

selected program.

(Warning: System does not

automatically stop the program.

Risk of damaging pump).

•

Fill tank (see 4.3), change program or

parameters.

Message

Description

Action

MSG-01:

SET THE VOLUME

•

Room volume has not been set

•

Set room volume end re-start

MSG-02:

WAITING START COMMAND

•

Indicates that START- command has not

been given

•

Press either F1 on display or Start on

remote control

MSG-03:

PUSH BUTTON OK START

•

Device has not been

„Start

-

activated“

(see 5.2.2)

•

Press Start-icon on display