Summary of Contents for SANARG 200AP

Page 2: ......

Page 4: ......

Page 8: ......

Page 24: ...24 PAGE LEFT INTENTIONALLY BLANK ...

Page 35: ...35 Figure 3 2 Electrical Input Connections 200AP ...

Page 60: ...60 PAGE LEFT INTENTIONALLY BLANK ...

Page 66: ...66 PAGE LEFT INTENTIONALLY BLANK ...

Page 79: ...79 PAGE LEFT INTENTIONALLY BLANK ...

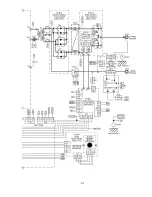

Page 80: ...80 10 1 INTERCONNECT DIAGRAM 200AP ...

Page 81: ...81 ...

Page 82: ...82 10 2 EXPLODED VIEW 200AP ...

Page 83: ...83 ...

Page 84: ...84 PAGE LEFT INTENTIONALLY BLANK ...

Page 89: ...PAGE LEFT INTENTIONALLY BLANK ...