The measurements shown are for reference only. Products and specifications shown are subject to change without notice.

www.santecfaucet.com | P: 310.542.0063 F: 310.542.5681

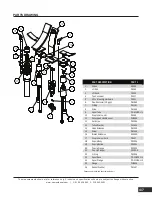

PARTS DRAWING

* Please specify the finish when ordering the part.

4/7

PART DESCRIPTION

PART #

1

Shank

K-2550

2

Lift Rod

P0264

3

Lift Knob

P0338

4

Tee Connector

P0427

5

5 Pcs. Mounting Hardware

P0431

6

Flow Restrictor (1.5 gpm)

PM-080

7

O-Ring

PM-151

8

Screw

PM-509

9

Spout Tube

PS-2CU00-U-1

10

Drop In Valve - Hot

P0466

11

Widespread Handle Lever

PH0086

12

Set Screw

PM-056

13

Teflon Washer

PM-099

14

Valve Extension

PM-348

15

Screw

PM-439

16

Broach Extension

SA240S

17

Drop In Valve - Cold

P0467

18

Pop Up Body

P0202-X

19

Pop Up Botton

P0202-1

20

Pop Up Flange

P0202-2

21

Pop Up Plunger

P0202-3

22

O-Ring

PM-006

23

Spout Base

PS-2NV00-U-1

24

Spout Flange

PS-2CU00-U-3

25

Flange

PH0016

26

Rubber Washer

PM-407