Troubleshooting

Safety, Operation and Maintenance Manual - Aug 2012

6-39

SY115C9/135C/155H Crawler Hydraulic Excavator

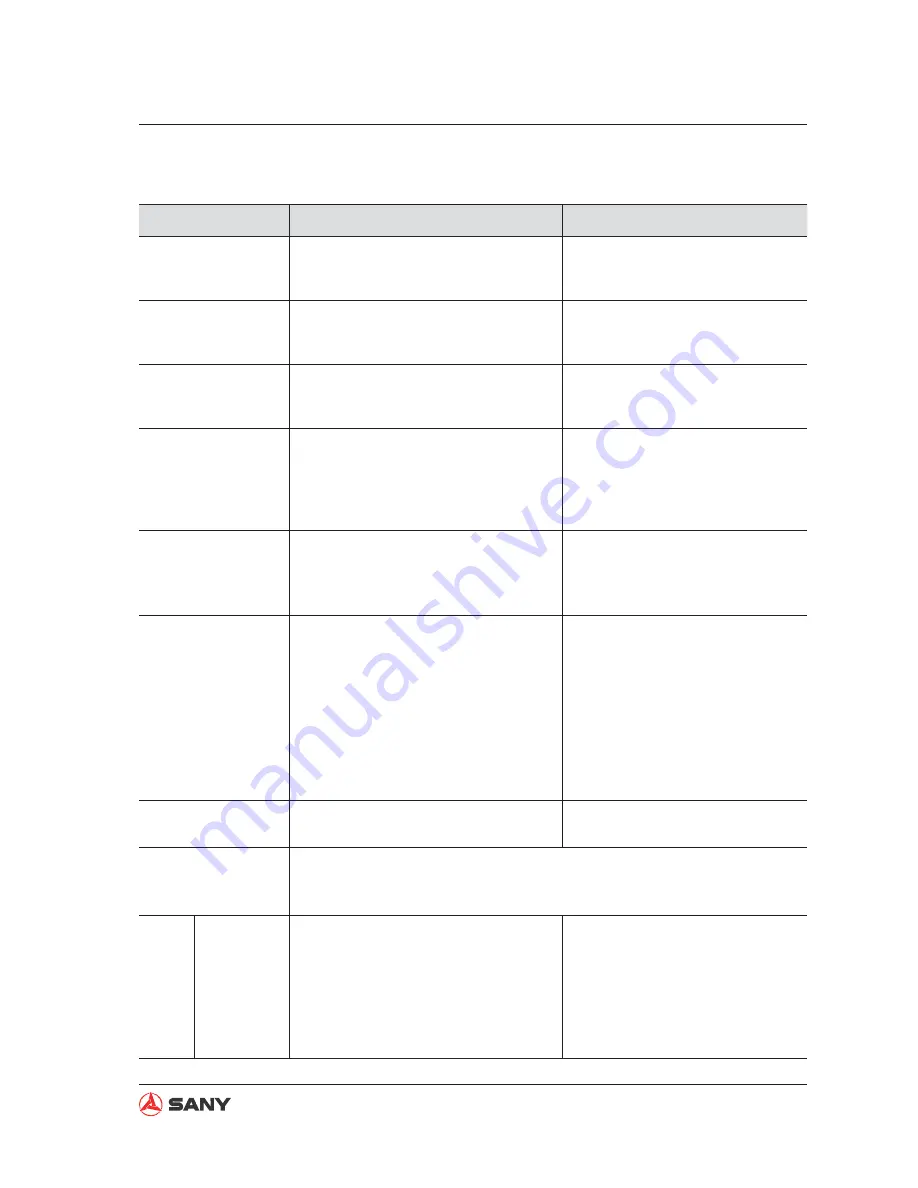

6.10 Other Common Failures

Failure

Causes

Remedy

Structure member

noise loud

●

Loose fastener

●

Bigger clearance between arm and buck-

et end faces due to wear

●

Check and retighten.

●

Reduce the clearance to a value that

is smaller than 1mm.

Bucket tip falls off dur-

ing operation.

●

Spring deformed and weak due to re-

peated use of bucket tip pin

●

Bucket tip pin not matching the adaptor

●

Replace bucket tip pin

Track kinks.

●

Loose track

●

Traveling at high speed on rough road in

the direction of sprocket

●

Tighten the track

●

Travel slowly on rough road in the

direction of idler.

Fan not working

●

Improper electrical connection or con-

nector contact

●

Air

fl

ow control switch, relay or tempera-

ture control switch damaged

●

Fuse exploded or battery voltage low

●

Repair/replace.

Fan running but pro-

ducing less air

fl

ow

●

Air intake side blocked

●

Evaporator or condenser fin plugged,

giving ineffective heat conduction

●

Fan vane seized or damaged

●

Clean/replace.

Compressor not work-

ing or working with dif

fi

-

culty

●

Compressor clutch not picking up due to

wire break or defective contact of electri-

cal circuit

●

Loose compressor belt

●

Wire break or failure of compressor

clutch coil

●

Insuf

fi

cient or excessive refrigerant

●

Repair

●

Adjust the tension of compressor

belt

●

Replace clutch coil

●

Refill/drain the refrigerant to a suit-

able level

Refrigerant insuf

fi

cient

●

Refrigerant leaks.

●

Insuf

fi

cient re

fi

lling

●

Eliminate the leaking point.

●

Re

fi

ll suitable amount of refrigerant.

High/low pressure

reading in normal op-

eration

Ambient temperature

:

30

~

50

℃

High pressure gauge: 1.47

~

1.67MPa

(

15

~

17kgf/cm2

)

Low pressure gauge: 0.13

~

0.20MPa

(

1.4

~

2.11kgf/cm2

)

Low pressure gauge

reads higher

.

Low pressure

tube surface

frosted

●

Expansion valve opening excessively.

●

Defective contact of expansion valve

thermo-bulb

●

Excessive refrigerant in the system

●

Replace expansion valve.

●

Install thermo-bulb correctly.

●

Drain refrigerant to the specified

level.