SY50U Excavator OMM

Maintenance

SANY

Operation and Maintenance Manual — 0120

5-55

TABLE OF

CONTENTS

INTRODUCTION

SAFETY

MACHINE

CONTROLS

MACHINE

OPERA

TION

MAINTENANCE

SPECIFICA

TIONS

OPTIONAL

EQUIPMENT

Track Assembly

Check the Track Tension

1. Use the bucket to lift the track on one side. Place an appropriate supporting device under the frame.

2. Rotate the raised track one full revolution.

3. Prepare the machine for service. See “Maintenance Safety” on page

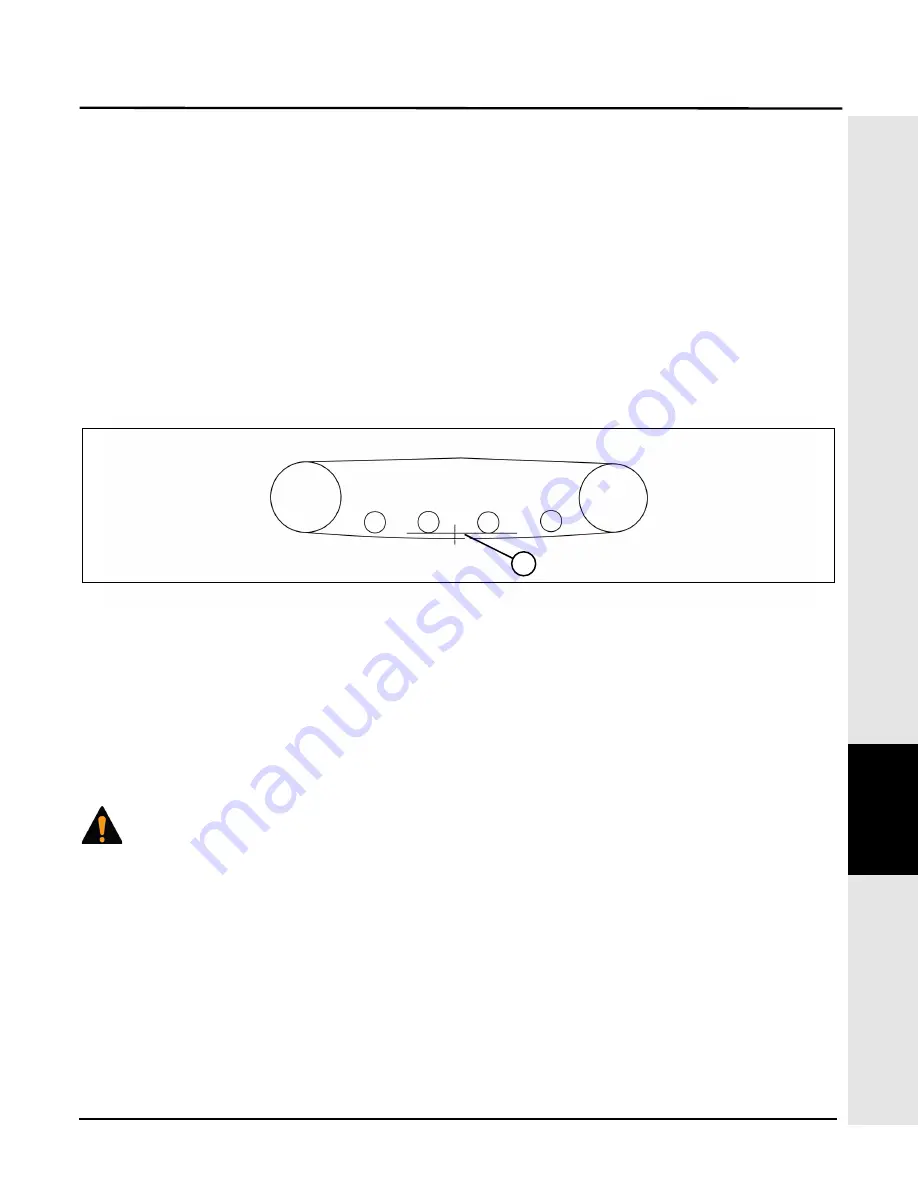

4. Use a straightedge to measure the track sag (1) between the tread of the roller and the rail surface of the track.

5. Normal track sag is 0.4

in.–0.8 in. (10 mm–20

mm) for rubber tracks and 0.6 in.–1.0 in. (15 mm–25 mm) for

steel tracks. If the track sag is outside of this range, the track tension must be adjusted.

Adjust the Track Tension

Increase the Track Tension

NOTICE!

Remove gravel or mud buildup between the sprocket and the track before checking track

tension.

WARNING!

•

The track tension grease fitting is under extreme pressure and grease exiting the valve can

cause serious injury.

•

Do not stand directly in front of the track tension grease fitting valve when loosening the

valve.

•

If track tension does not release after opening the grease valve, never attempt to remove

the track or disassemble any component before the pressure is released.

Failure to follow these warnings could result in death or serious injury.

Fig. 5-49

0001642

1