MAINTENANCE

5-31

SY60C Excavator OMM

NOTE:

Always use SANY-approved breather filters.

6.

Install the new filter. Tighten the cover and cap

securely.

NOTICE!

Dispose of the filter in accordance with all

applicable environmental regulations. Failure to

do so could result in damage to the environment.

Replace the Hydraulic Oil Pilot Filter

WARNING

• Allow the hydraulic system to cool before

servicing. Hot oil may cause burns or other

serious injury.

• The hydraulic tank may be under pressure, and

hydraulic oil may be present at the filter cover.

Relieve any pressure to prevent injury.

Failure to follow these warnings could result in

death or serious injury.

1.

Prepare the machine for service. See “Maintenance

Safety” on page 2-5.

2.

Relieve system pressure. See “Relieve Hydraulic

System Pressure” on page 5-29.

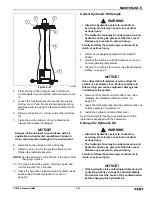

0003125

Figure 5-43

3.

Place a container under the pilot filter bowl (1) to

catch any spilled oil.

4.

Loosen and remove the pilot filter bowl.

NOTICE!

Dispose of the contaminated oil and filter in

accordance with all applicable environmental

regulations. Failure to do so could result in

damage to the environment.

5.

Remove the filter element from the housing. Use a

lint free cloth to clean the interior of the housing and

bowl.

NOTE:

Always use SANY-approved oil filters.

6.

Install a new filter element, gasket, and O-ring.

7.

Install the filter bowl and tighten securely.

8.

To purge air from the system, start the engine and

run at low idle for 10 minutes.

9.

Check the hydraulic oil level and add hydraulic oil as

needed. See “Check Hydraulic Oil Level” on

page 4-8.

Replace the Hydraulic Oil Return Filter

WARNING

• Allow the hydraulic system to cool before

servicing. Hot oil may cause burns or other

serious injury.

• The hydraulic tank may be under pressure, and

hydraulic oil may be present at the filter cover.

Relieve any pressure to prevent injury.

Failure to follow these warnings could result in

death or serious injury.

NOTICE!

Examine the return filter for metal chips and

debris. An excessive amount of bronze and steel

chips indicates that the hydraulic pump or a

hydraulic motor has been damaged. Rubber

debris indicates seal and/or gasket damage.

Inspect these components before filling the

hydraulic tank and returning the machine to

service.

1.

Prepare the machine for service. See “Maintenance

Safety” on page 2-5.

2.

Relieve system pressure. See “Relieve Hydraulic

System Pressure” on page 5-29.

3.

Remove the top access panel. See “Add Hydraulic

Oil” on page 5-29.

0003037

Figure 5-44

1

2

1