MAINTENANCE

5-35

SY60C Excavator OMM

Track Assembly

Check the Track Tension

NOTICE!

Remove gravel or mud buildup between the

sprocket and the track before checking track

tension.

1.

Use the bucket as a support to lift the track on one

side.

2.

Rotate the track one full revolution.

3.

Prepare the machine for service. See “Maintenance

Safety” on page 2-5.

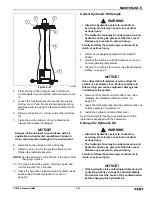

0002345

Figure 5-50

4.

Use a straightedge to measure the track sag (1)

between the tread of the roller and the rail surface of

the track.

5.

Normal track sag is 0.4 in.–0.8 in. (10 mm–20 mm)

for rubber tracks and 0.6 in.–1.0 in. (15 mm–25 mm)

for steel tracks. If the track sag is outside of this

range, the track tension must be adjusted.

Adjust the Track Tension

WARNING

• The track tension grease fitting is under extreme

pressure and grease can exit the grease valve

and cause serious injury.

• Wear safety goggles, gloves, and other personal

protective equipment (PPE) to prevent serious

injury.

• Do not stand directly in front of the track tension

grease fitting valve when loosening the valve.

Failure to follow these warnings could result in

death or serious injury.

WARNING

• If the track remains too tight after opening the

track tension grease valve, or if the track remains

too loose after adding grease to the track tension

grease fitting, do not attempt to remove the track

or remove the track adjuster. If this occurs,

contact a SANY dealer for further instructions.

• Pressurized grease inside the track adjuster may

cause serious injury if any component is

disassembled before pressure is released.

Failure to follow these precautions could result

in injury.

1.

Use the bucket as a support to lift the track on one

side.

2.

Prepare the machine for service. See “Maintenance

Safety” on page 2-5.

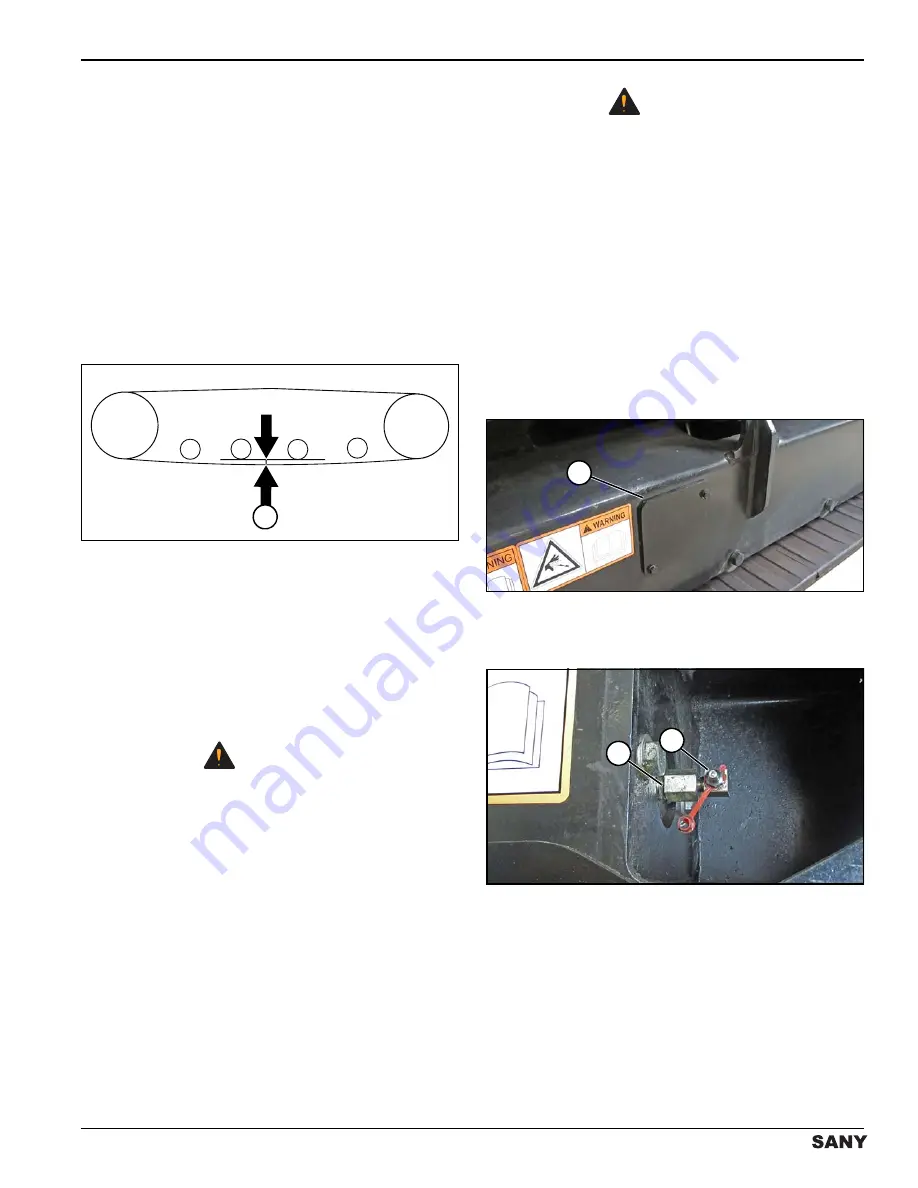

0003038

Figure 5-51

3.

Loosen the fasteners securing the track tension

adjuster cover (1). Rotate the cover open.

0003039

Figure 5-52

Increase the Track Tension

1.

Prepare the machine for service. See “Maintenance

Safety” on page 2-5.

2.

Make sure that the grease valve (2) is closed tightly.

3.

Using a grease gun, pump grease into the grease

fitting (3) while observing idler movement.

4.

Rotate the track one full revolution. Check the track

tension to confirm adjustment.

5.

Position the adjuster cover and tighten the fasteners.

1

1

2

3