85464849248002

REFERENCE NO.

SM

831148-2

FILE NO.

TECHNICAL DATA

&

SERVICE MANUAL

1

2

3

4

5

6

Section

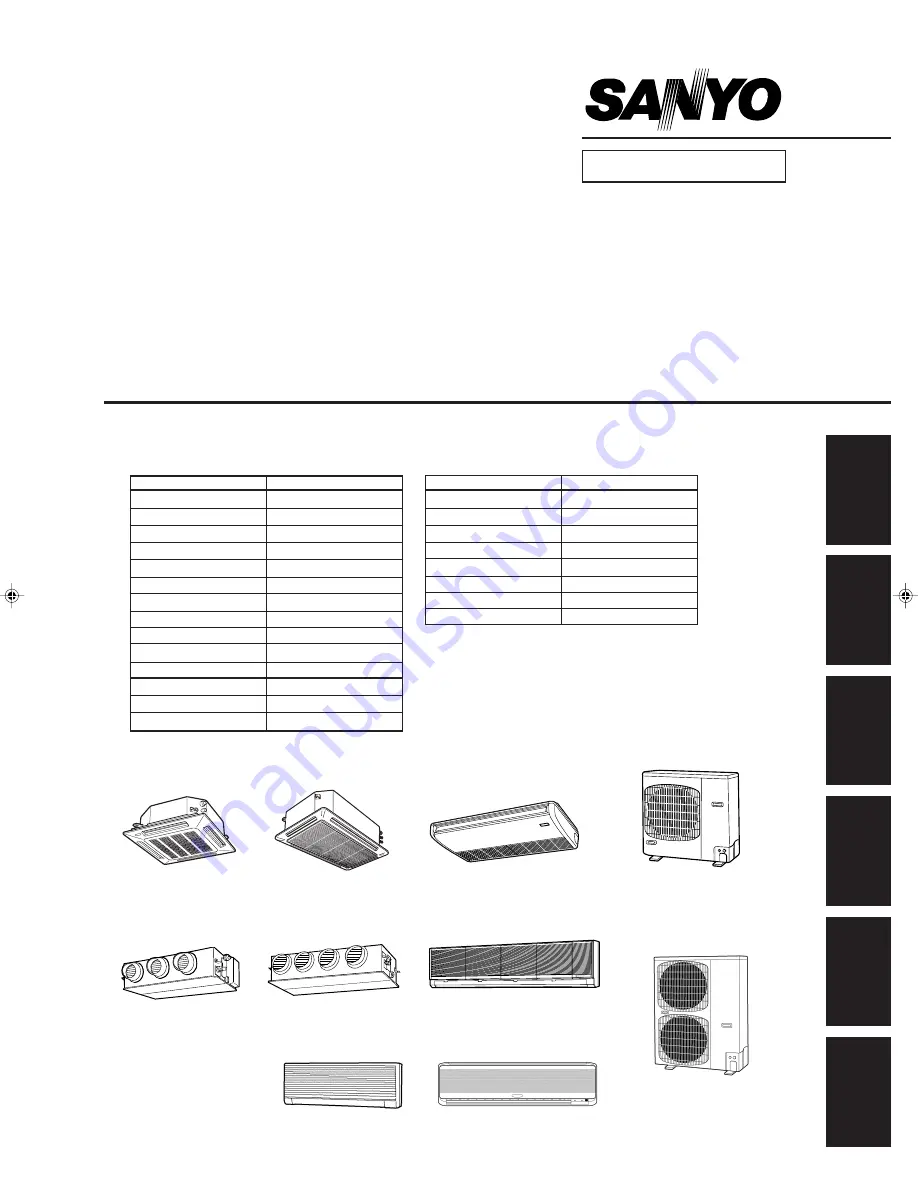

XH2672R / CH2672R, C2672R

XH3672R / CH3672R, C3672R

XH4272R / CH4272R, C4272R

TH2672R / CH2672R, C2672R

TH3672R / CH3672R, C3672R

THH2672R / CH2672R

THH3672R / CH3672R

TH4272R / CH4272R, C4272R

KH2672R / CH2672R, C2672R

KH3072R / CH3072R, C3072R

KH3672R / CH3672R, C3672R

KHH2672R / CH2672R

UH2672R / CH2672R, C2672R

UH3672R / CH3672R, C3672R

SPLIT SYSTEM AIR CONDITIONER

XH2672R

XH3672R

XH4272R

CH4272R, C4272R

UH2672R

TH2672R, THH2672R

TH3672R, THH3672R

TH4272R

CH2672R, C2672R

CH3072R, C3072R

CH3672R, C3672R

KH3072R

KH3672R

Indoor Unit

Outdoor Unit

UH3672R

KHH2672R

KH2672R

OUTDOOR MODEL No.

PRODUCT CODE No.

CH2672R

854 028 20

CH3072R

854 028 21

CH3672R

854 028 22

CH4272R

854 031 87

C2672R

854 028 24

C3072R

854 028 25

C3672R

854 028 26

C4272R

854 031 88

INDOOR MODEL No.

PRODUCT CODE No.

XH2672R

854 028 32

XH3672R

854 028 33

XH4272R

854 031 89

TH2672R

854 028 35

TH3672R

854 028 36

TH4272R

854 031 90

THH2672R

854 028 38

THH3672R

854 028 39

KH2672R

854 028 28

KH3072R

854 028 29

KH3672R

854 028 30

KHH2672R

854 028 31

UH2672R

854 028 40

UH3672R

854 028 41

Summary of Contents for 000 BTU Ductless Single Zone Mini-Split Wall-Mounted Heat Pump

Page 2: ......

Page 77: ...1 2 3 4 5 6 I 73 SM831148 1 Specifications 1 4 Dimensional Data B Outdoor Unit CH4272R C4272R ...

Page 118: ......

Page 128: ...1 2 3 4 5 6 III 10 SM831148 3 Electrical data Wall Mounted Type KH2672R ...

Page 129: ...III 11 SM831148 3 Electrical data 1 2 3 4 5 6 Wall Mounted Type KH2672R Schematic Diagram ...

Page 133: ...III 15 SM831148 3 Electrical data 1 2 3 4 5 6 Wall Mounted Type KHH2672R Schematic Diagram ...

Page 135: ...III 17 SM831148 3 Electrical data 1 2 3 4 5 6 3 2 Outdoor Units CH2672R Schematic Diagram ...

Page 137: ...III 19 SM831148 3 Electrical data 1 2 3 4 5 6 3 2 Outdoor Units C2672R Schematic Diagram ...

Page 143: ...III 25 SM831148 3 Electrical data 1 2 3 4 5 6 3 2 Outdoor Units CH4272R Schematic Diagram ...

Page 145: ...III 27 SM831148 3 Electrical data 1 2 3 4 5 6 3 2 Outdoor Units C4272R Schematic Diagram ...

Page 146: ......